USHIO introduces a UV-LED drying device for sheetfed offset printing presses.

Achieves and maintains high irradiance and high dose energy even at long distances

On August 1, Ushio Inc. (Ushio hereafter; head office: Tokyo; President and CEO: Kenji Hamashima) will introduce the "UniJet A1220", a new UV-LED drying device for sheetfed offset printing presses as part of its new "UniJet Series" of high-performance drying devices.

The actual device will be exhibited at IGAS 2018 (Booth No. 3-21) to be held at Tokyo Big Sight from July 26–31.

With the printing industry demanding greater energy efficiency and longer operating life in order to reduce TCO*1 of processes such as sheetfed offset printing, conventional light sources for curing UV printing inks are rapidly being replaced with LEDs. However, the high-speed sheetfed offset printing process makes print media (paper,etc.) flutter, which requires maintaining a certain distance between the light source and media. With conventional LEDs, irradiance drops off with distance, resulting in insufficient ink hardening (See figure below).

Conventional LEDs USHIO’s UniJet A1220

USHIO resolved this problem by combining technologies such as optical simulation and lens design that were cultivated during the development and production of its UV lamps together with its own independently-developed high-density LED mounting technology to develop a UV-LED drying device that maintains high irradiance and high dose energy*2 even at longer irradiation distances.

This device achieves the energy savings and long life that are characteristics of LEDs together with the curing performance of conventional lamps.

USHIO will continue leveraging its expertise in light to reduce TCO conservation and improve quality in the printing industry.

■Main Features

(1) Achieves and maintains high irradiance and high dose energy even at long distances.

USHIO’s unique technology delivers irradiance of 10.5 W/cm2 at an irradiation distance of up to 80 mm. Attainment of a high light integral, the most important element of performance in UV curing, contributes to increased printing productivity and quality.

(2)Two types developed with practical irradiation distances of 40 mm and 80 mm.

Select the type that is best suited to your printing environment.

(3) Allows divided irradiation (in 8 steps).

Optimum irradiation width can be selected according to width of media.

(4) Provides continuously variable light adjustment (from 10% to 100%).

LED irradiance can be adjusted in the range 10%–100% according to printing speed.

■Specifications

※1 Reference value based on measurement by USHIO.

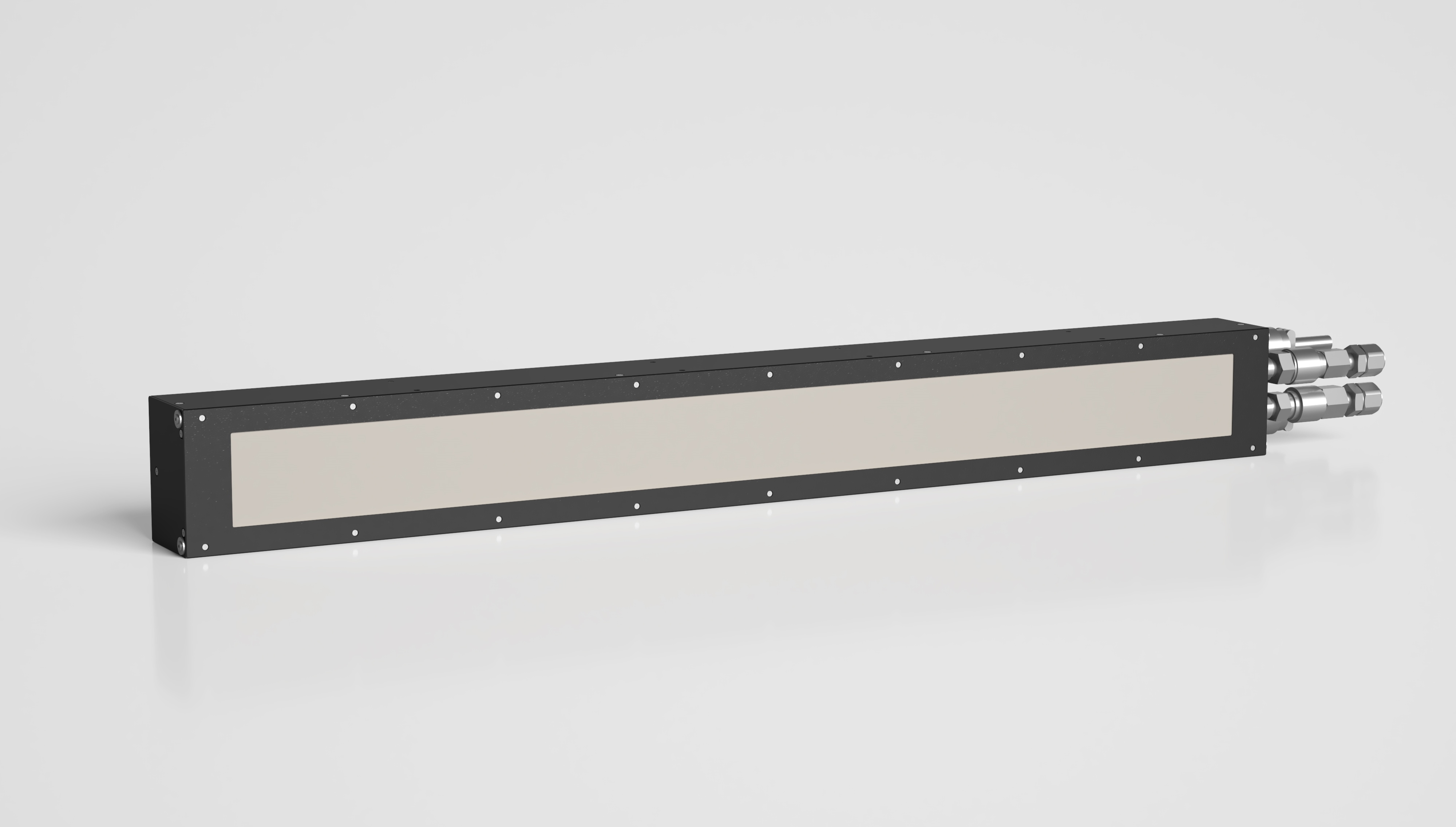

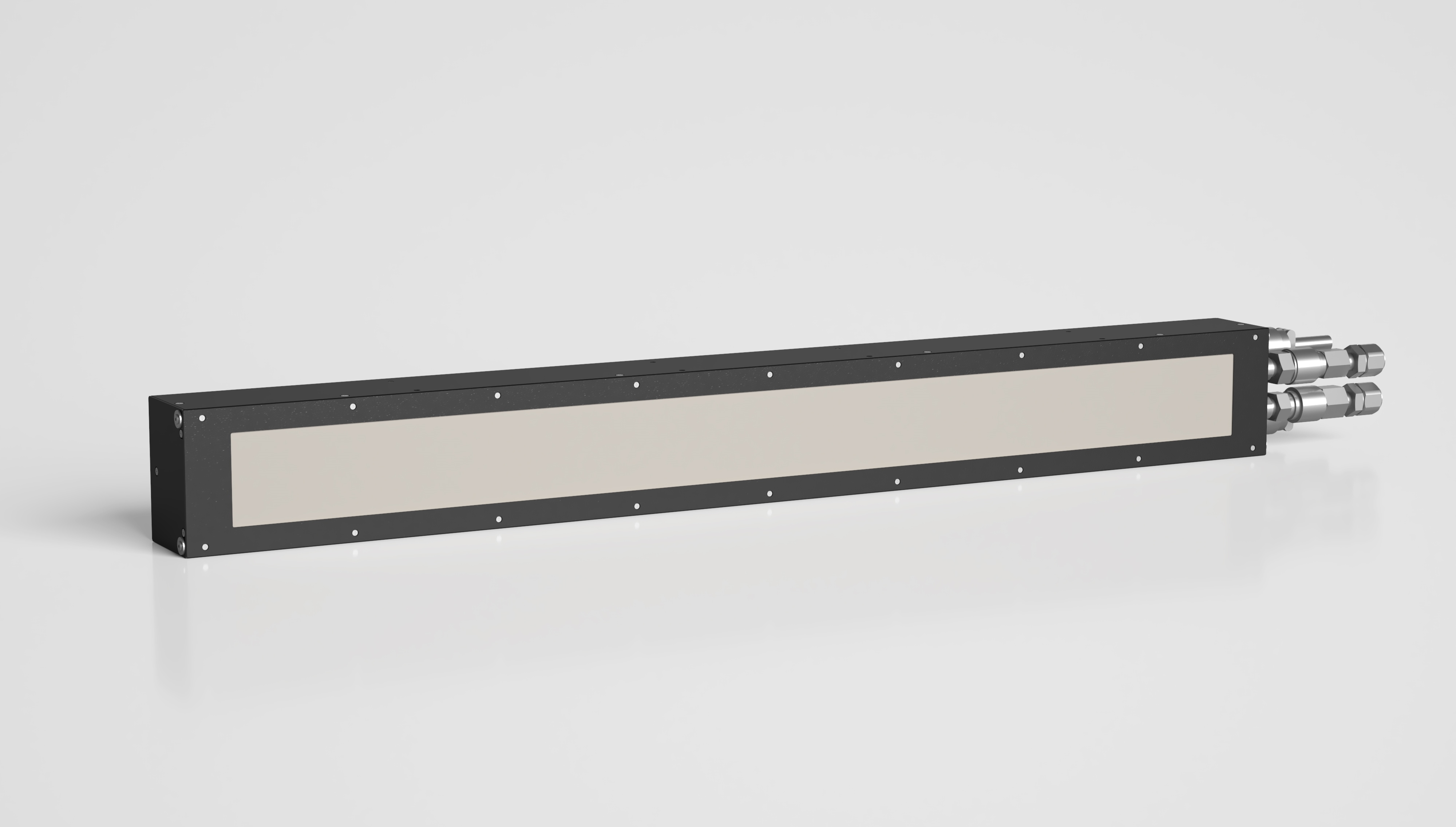

■Product Image

The actual device will be exhibited at IGAS 2018 (Booth No. 3-21) to be held at Tokyo Big Sight from July 26–31.

With the printing industry demanding greater energy efficiency and longer operating life in order to reduce TCO*1 of processes such as sheetfed offset printing, conventional light sources for curing UV printing inks are rapidly being replaced with LEDs. However, the high-speed sheetfed offset printing process makes print media (paper,etc.) flutter, which requires maintaining a certain distance between the light source and media. With conventional LEDs, irradiance drops off with distance, resulting in insufficient ink hardening (See figure below).

Conventional LEDs USHIO’s UniJet A1220

USHIO resolved this problem by combining technologies such as optical simulation and lens design that were cultivated during the development and production of its UV lamps together with its own independently-developed high-density LED mounting technology to develop a UV-LED drying device that maintains high irradiance and high dose energy*2 even at longer irradiation distances.

This device achieves the energy savings and long life that are characteristics of LEDs together with the curing performance of conventional lamps.

USHIO will continue leveraging its expertise in light to reduce TCO conservation and improve quality in the printing industry.

| *1 Stands for Total Cost of Ownership. Indicates the total cost of assets such as equipment from purchase through disposal based on expenditure of time and money. *2 The quantity of light required to cure UV printing inks. Indicates the product of UV intensity and curing time, or light dosage within the hardening time. |

■Main Features

(1) Achieves and maintains high irradiance and high dose energy even at long distances.

USHIO’s unique technology delivers irradiance of 10.5 W/cm2 at an irradiation distance of up to 80 mm. Attainment of a high light integral, the most important element of performance in UV curing, contributes to increased printing productivity and quality.

(2)Two types developed with practical irradiation distances of 40 mm and 80 mm.

Select the type that is best suited to your printing environment.

(3) Allows divided irradiation (in 8 steps).

Optimum irradiation width can be selected according to width of media.

(4) Provides continuously variable light adjustment (from 10% to 100%).

LED irradiance can be adjusted in the range 10%–100% according to printing speed.

■Specifications

| A1220 | WD40mm | WD80mm |

| Window Size (mm) | 1221.2*56 | 1221.2*96 |

| Width (mm) | 1320 | |

| Length (mm) | 100 | 150 |

| Height (mm) | 105 | |

| Peak Irradiance (W/cm2) 385 nm |

10.5 (WD=40mm)※1 | 10.5 (WD=80mm)※1 |

■Product Image