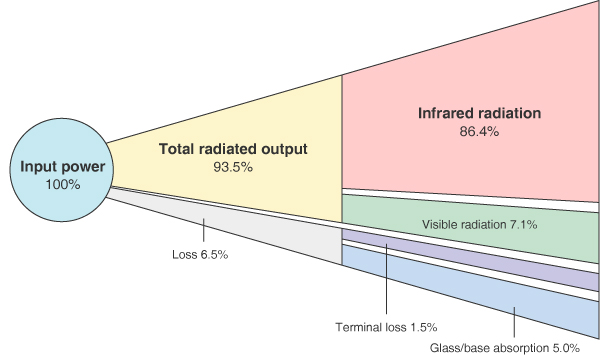

Highly efficient energy sources

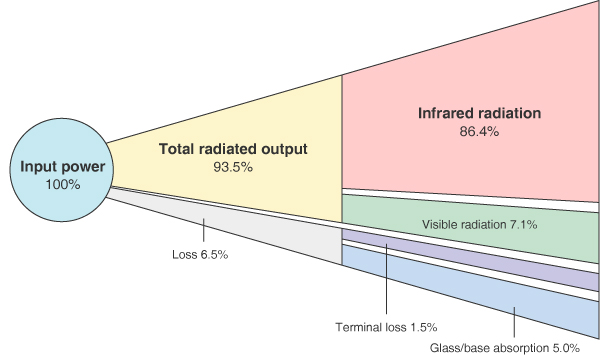

Over 85% of the input power is converted to infrared radiation for a highly efficient lamp-type radiant heat source.

Reduced power consumption means lower running costs.

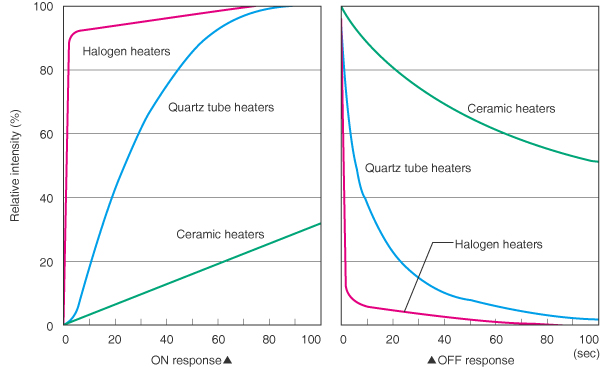

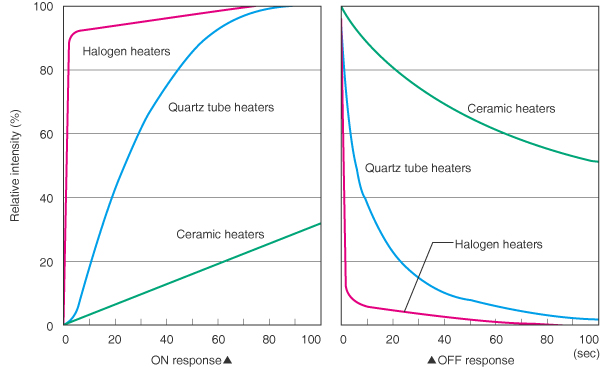

Excellent heating and cooling performance

Non-contact rapid heating and cooling is achieved by a low-heat-capacity tungsten filament.

For example, it is possible to heat aluminum to 300℃ in only 10 seconds.

By reducing heating times, processing capabilities have been improved.

In addition, unlike resistive heating that continually consumes power, the ability to be ON or OFF as needed lowers running costs.

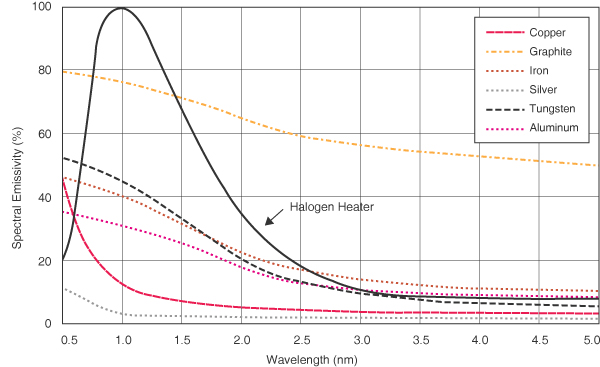

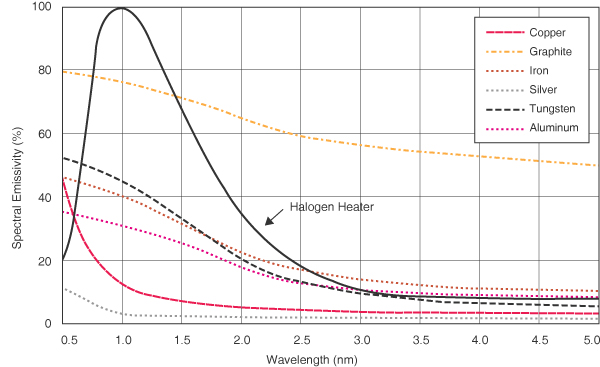

Wavelength of light matches the material absorption characteristics

Matching the absorption characteristics of various metals and the wavelength output of halogen lamp heaters, enables high efficiency, as well as, heating processes that are not possible with high-frequency heating and hot air.

Highly controllable

Superior thermal control has been achieved through the optically designed heater unit and dedicated PID control system that other heat sources cannot match.

A non-contact in-plane temperature ±5% distribution has been achieved.

Compact, clean heat source

Halogen lamp heaters can be installed in narrow spaces since they can output a large amount of energy in spite of their small size and light weight. In addition, maintaining a clean atmosphere or whether heating in air or a vacuum are not issues for non-contact heating. Photoheating also emits no gases, so it can contribute to CO2 emission reduction.

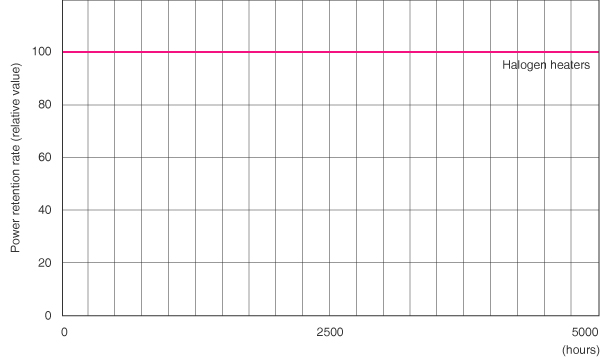

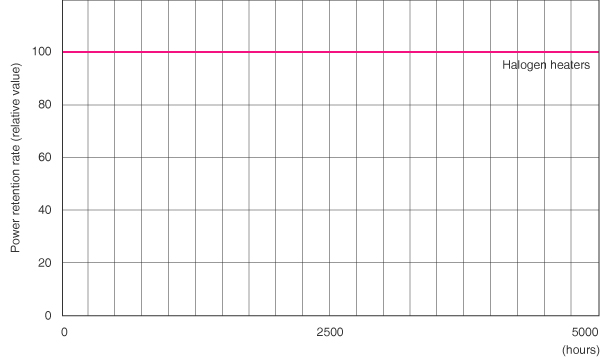

Constant-energy emission over long lifespan

Using the halogen cycle enables a design with a long lifespan unmatched by other halogen lamp heaters. Furthermore, as there are no changes over time as with other heat sources, near constant-energy emission is maintained over the entire lifespan and results in improved maintainability.