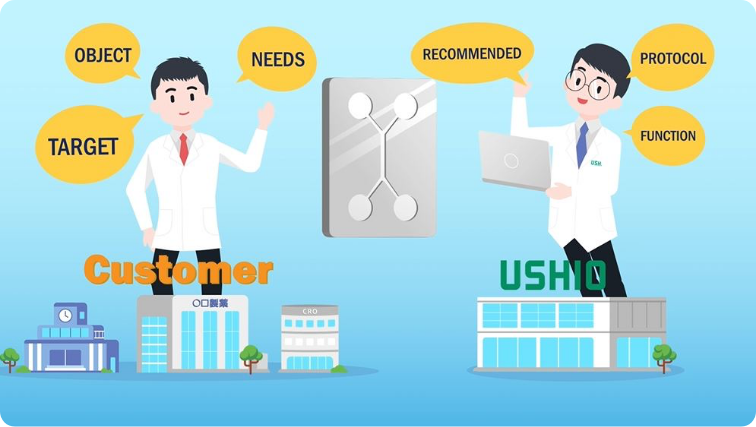

Open Innovation Platform

Agile Development Service

The development of Organs On Chip (MPS) involves design fabrication to address non-obvious issues.

This is a difficult task for customers to do on their own.

However, OoC development is essential for new drug development.

In such a situation, the Open Innovation Platform provided by Ushio might prove useful.

MODEL CASE

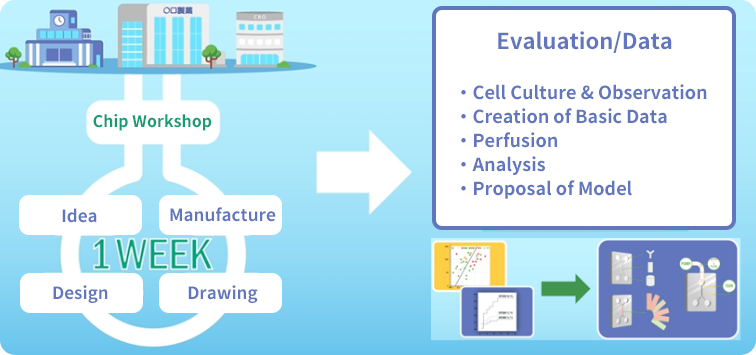

Trial、Improvement、Mass Production

- STEP1Trial

- We hear out your ideas, requests, and required functions for in vitro experiments, and propose a chip design based on them. After your approval and order placement, we commence the manufacture of the chip. The trial product can be manufactured in at least 1 week.

- STEP2Improvement

- Based on your feedback of the trial product, we discuss the points for improvement and the next chip design. Until you are satisfied with the product, we repeat speedily the process of development and feedback.

- STEP3Mass Production

- After confirming the chip design, we propose the means of mass production and supply. We will also ask for your desired microplate size for lab automation. Please discuss with us your plans for implementing the chip into your project or routine experiments, the required number of chips etc.

Request by customer

In order to closely recapitulate 3D biological tissue structures,

a substitute for membrane inserts was desired.

The customer considered the construction of an evaluation system that could recapitulate 3D tissue structures up to the cell layer level. On conventional membrane inserts, cell migration and cell-to-cell interactions were not sufficiently functional, so discussions on the manufacture of a chip were carried out. From the desired concept, the testing of the trial chip, the transformation into a usable product, and discussions on improvements proceeded smoothly, and the merits of each stage were felt by the customer.

CASE STUDY

Trial & Improvement Concept

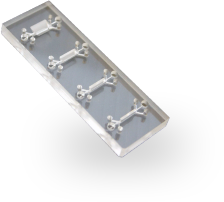

Prototype Chip

Based on a concept, we realized a chip design. In this stage, the investigation of conditions was necessary, so a wide variety of chips was fabricated.

Improved Chip

We evaluated whether the chip would work as planned after the introduction of the gel and whether cell culture was possible. We revised the channel length and the number of ports, and these changes were reflected in the next trial product.

Completed Final Product

Since the shape is more or less confirmed, we established the overall design, including the surrounding structure such as reservoirs.

The reservoirs for filling with culture medium was also of sufficient capacity.

Introduction to Ushio’s Open Innovation Platform (Organs on Chip)

Photobonding® Technology

CONTACT

Please contact us to inquire about

our products or technical services.