Solid-state light sources operate on a completely different principle from most traditional types of lights. They are made of materials that glow when electricity is passed through them, and the wavelength of light emitted can be changed by altering the composition of the material. The name “solid-state light sources (SSLSs)” may not be widely known, but the products— LEDs, laser diodes (LDs) and organic electroluminescent (EL) materials are becoming familiar, and the technology is advancing rapidly, accelerating the evolution of light. This feature describes the most common type of solid-state light source now in use: LEDs.

A New Take on an Old Technology

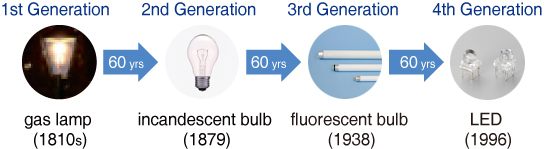

Light-emitting diodes, or LEDs, are often described as “fourth generation” light sources, following on from the first three generations of lighting represented by candles and gas lamps, incandescent bulbs, and fluorescent lights. However, the technology behind LEDs was first discovered as early as 1907. In the 1960s, LEDs that emit red, green or orange light were developed, but the range of wavelengths was narrow, and the light emitted was dim. Consequently, they were only suitable for such uses as the displays of electronics products.

Advances in Lghting Technology

Since the 1810s, when gas lighting began to be used on a widespread basis, new advances in lighting technology have been made about once every 60 years.

In 1993, however, the technology took a major step forward when blue LEDs were developed. Since LEDs could now generate all three of the primary colors that make up “white” light—red, green and blue—the three could be combined to generate the sort of light that provides full illumination. In 1996, the first “whitelight LED” was developed, using blue LEDs as the base. At last, some 90 years after the principle of LEDs was discovered, the path was clear for LEDs to be used on a full-scale basis for illumination.

Three Primary Colors Combine to Make a “White” LED

The development of a blue LED made it possible to create natural, “white” light by combining the three primary colors of light (Figure 1). Another method of creating “white” light is to shine blue LEDs onto a fluorescent material, which then emits the full spectrum of light (Figure 2). Both methods are used, for differing applications.

How Do LEDs Generate Light?

LEDs are made of semiconductors commonly used in computers and other electronics. Semiconductors which have a positive charge are called “p-type semiconductors,” while those that have a negative charge are called “n-type semiconductors.” These two types are joined together to make an LED. Even before electricity is passed through the material, there is some charge; however, when the semiconductor is connected to an electric circuit and energized, negative charge accumulates inside the n-type semiconductor, and positive charge accumulates in the p-type semiconductor until both the materials are saturated with charge. Semiconductors, by nature, will try to return to an uncharged state. To do so, they must release their extra charge. As the positively and negatively charged semiconductors are joined to one another, at the interface between the two materials the positive and negative charges continuously cancel each other out, discharging the semiconductors and releasing energy in the form of light.

Principle of Light Generation by an LED

This structure can be used in reverse, by solar power cells, to generate electricity. By shining light on the chip, the positive and negative charges accumulate in the light-emitting layer and can be connected to a power circuit.

Low Energy Consumption and Long Operating Life

LEDs are very efficient at converting electricity into visible light, when compared to other lighting devices. The energy emitted as visible light by an incandescent bulb is no more than 10% of the energy input in the form of electricity (i.e., the conversion efficiency is 10% or less). Fluorescent bulbs have a conversion efficiency of around 20%. The vast majority of the energy is converted into either ultraviolet radiation or infrared radiation (heat).

The conversion efficiency of LEDs, on the other hand, is around 30% to 50%. Since solid-state light sources emit only a single “useless” wavelength, and much more is radiated as visible light. As a result, LEDs consume much less energy to generate a given amount of light compared with other light sources.

Another useful feature of LEDs is that they have a very long operating life. Incandescent light bulbs generate light from a thin filament, which gets very hot when it is operating. The heat slowly weakens and degrades the material, and after being used for a certain length of time, the filament will snap. In the case of fluorescent bulbs, the electrodes heat up and start to react with the phosphorescent material. Eventually, a metallic residue accumulates at the ends of the bulb near the electrodes, and that part of the bulb will grow darker. In addition, the bulbs function by emitting ultraviolet light, which the phosphorescent coating on the inside of the bulb converts to visible light. Over time, the phosphorescent material will gradually degrade and produce less and less visible light, reducing both energy efficiency and the effectiveness of the lighting.

By contrast, LEDs emit light directly from the semiconductor itself – a solid, and very long-lasting piece of silicon. Although LEDs do wear out eventually, in most cases it is because the heat that they generate slowly degrades the electronic components surrounding the semiconductor, or the electrical wires leading to the semiconductor are damaged.

Challenges Facing SSLSs

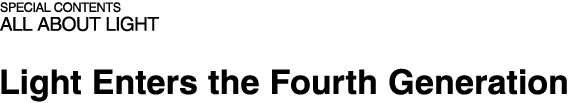

The light sources used for the scanning units of office equipment, and for the backlight units of large-screen monitors have generally been discharge-type lamps, such as xenon lamps or other rare-gas fluorescent lamps. However, these light sources are gradually being replaced by LEDs, LDs and other SSLSs in order to reduce environmental impact by cutting energy consumption and to address consumer needs for reducing the size of products.

However, at present, the main application of LEDs is for basic lighting purposes. The brightness and luminance of single-body light sources is still a bit too low for them to be used effectively for industrial applications that use light as energy such as in photolithography, to make semiconductors, LCDs and electronic components, or in UV curing. Applications which require high light uniformity and collimation, meanwhile, will require further advances in optics technology.

The companies in the USHIO Group possess a wide variety of optical technologies which will help to leverage the strengths of SSLSs. In addition to efforts to increase the brightness and luminance of the light sources themselves, the group is developing optical mirrors and lenses, modular designs, and other types of optical technology improvements that can be combined with SSLSs to steadily enhance their performance. By resolving the shortcomings and making the light more suitable for certain applications, SSLSs will gradually be adopted for industrial applications. The USHIO Group aims to use this technology to develop total solutions by adapting the characteristics of the light source and its lighting specifications to precisely match the application.

SSLSs Can Meet the Demands for a New Type of Light Source

Over time, we are learning more and more about the specific characteristics and functions of each different wavelength of light. For example, light with a wavelength of 146nm can break down carbon dioxide, while the 172nm wavelength breaks down oxides of nitrogen and sulfur. The 254nm wavelength can be used for sterilization and disinfection, 308nm wavelengths can be used for skin treatment, the 365nm wavelength is used for UV curing and photolithography, and the 660nm wavelength is ideal for growing plants. At present, SSLSs are being developed to reproduce various wavelengths of light, and development efforts are under way to improve the brightness and luminance to levels which match those of discharge lamps. When these efforts reach fruition, SSLSs will take on a new role of generating light in a specific wavelength to perform a particular function.

Discharge lamps generate not only the desired wavelength of light, but also shorter and longer wavelengths. Filters must be used to screen out the unnecessary wavelengths, depending on the type of application for which they are used. However, SSLSs emit light in only a very narrow spectrum. Furthermore, the wavelength that they emit is determined by the type of material used to make the semiconductors, so the production process is much simpler than that of a discharge lamp, and it is easier to generate a specific desired wavelength.

The life-giving light produced by the sun contains a multitude of different wavelengths, including many whose function or characteristics are unknown, and many that we have yet to generate by other means. However, as development work on SSLSs continues, we will unlock the secrets to generating and using these wavelengths, and be able to use them for new purposes and new applications. Clearly, our future with SSLSs is destined to be a “bright” one, in every sense of the word.

USHIO SSLSs

SSLSs have a multitude of potential applications. In addition to lighting, they can be used in various types of sensors and communications devices, horticulture, medical devices and in the production of semiconductors and LCDs. USHIO is leveraging its wealth of expertise in light technology to develop a multitude of new products and applications.

USHIO INC.

USHIO’s SSLSs are based on designs customized to meet the needs and aims of our customers. We deal with a wide range of applications from devices to lighting modules, as well as the equipment and systems that contain them. As a manufacturer of light, USHIO combines these light sources with its accumulated light technologies, including development of optical mirrors and lenses, and capabilities in module design, to provide the optimal light for every type of manufacturing process.

![]()

Spot UV curing equipment (LED)

High-power UV/LED module for curing ink in inkjet printers

LED module for document scanners in office equipment

LED modules

CHRISTIE DIGITAL SYSTEMS U.S.A., INC.

Modular displays with LED backlights

CHRISTIE DIGITAL SYSTEMS makes a variety of LED modules as well as producing and selling digital cinema projectors. The “Christie MicroTilesTM” display system is the world’s first modular-type display, using small, rectangular tiles that can be arranged in any pattern. The displays offer superior color hues and luminosity to LCD or plasma displays. The company is developing a third segment for its display business—digital signage—in addition to the current cinema market and non-cinema uses. This market is expected to grow rapidly.

CHRISTIE MEDICAL HOLDINGS, INC.

“VeinViewer®” vascular imaging system containing a near-infrared LED

CHRISTIE MEDICAL HOLDINGS was established in January 2010, shortly after USHIO subsidiary CHRISTIE DIGITAL SYSTEMS acquired the U.S.-based Luminetx Corporation, which forms the core of the new company. Luminetx Corporation, was a medical and biometrics company, renowned for introducing the “VeinViewer®” vascular imaging system containing a near-infrared LED, the world’s first product which can display real-time images of veins under the skin.

The “VeinViewer®” uses LEDs to generate both visible light and infrared light, locating the veins and projecting an image of them onto the surface of the skin, in real time. This makes it much easier for medical staff to locate veins and insert IV drip needles, or to give injections. This technology is gaining a great deal of interest, since it reduces the pain and trouble for patients, and saves time and expenses in health care settings.

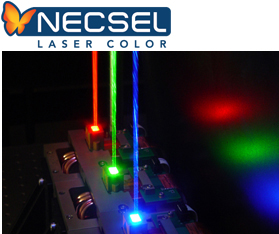

NECSEL INTELLECTUAL PROPERTY, INC.

Semiconductor laser used in a projection system

The company was established in November 2008, with the aim of developing and commercializing high-output lasers in the infrared and visible light frequency bands. In addition to a very simple structure, these lasers have high frequency conversion efficiency and are extremely reliable, making it possible to produce small, high-output lasers. The process for making these lasers is the same as that used for making semiconductor wafers, which is expected to lead to greater automation and lower costs. The company is currently working to develop these semiconductor lasers as the light sources for specialized lighting, digital cinema projectors, laser TVs and data projectors.

EPITEX INC.

Various types of LED elements/devices

EPITEX is a manufacturer of LEDs that specializes in distinctive products for the infrared spectrum band. The company has developed some of the best manufacturing technology in the industry for growing crystals, which can be used to produce small quantities with widely varied characteristics. The company sells custom-made, high-output infrared LED products for surveying equipment and car sensors for electronic toll collection gates. At the same time, the company is also working on the development of new light sensors for biometrics, auto-related, medical and industrial applications.

USHIO LIGHTING, INC.

The company manufactures and sells light sources and lighting equipment for commercial buildings, theatres, studios and other venues. USHIO LIGHTING holds a high share of the markets for halogen lamps and high-intensity discharge (HID) lamps, and is developing a lineup of LED products with the expectation that these products will further increase their share of these markets. The company is working to build its brand image, based on the slogan: “The light you need, when you need it, no more and no less.”

![]()

Illumination LEDs

Infrared LED for surveillance cameras

LED light bars

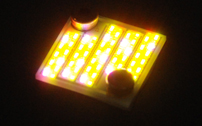

LED light panels

High integration LED module