Ushio releases a high-power blue laser module which achieved a significant cost reduction

― The module is expected to be used for heating and processing applications in a variety of manufacturing processes ―

Ushio Inc. (Head Office: Tokyo; President & CEO: Koji Naito; hereinafter “Ushio”) will release a blue laser module in November 2022, which is intended to be used for the heating and processing of metals such as gold and copper in a variety of manufacturing processes and has achieved significant cost reduction despite its high power with a fiber output of 25W.

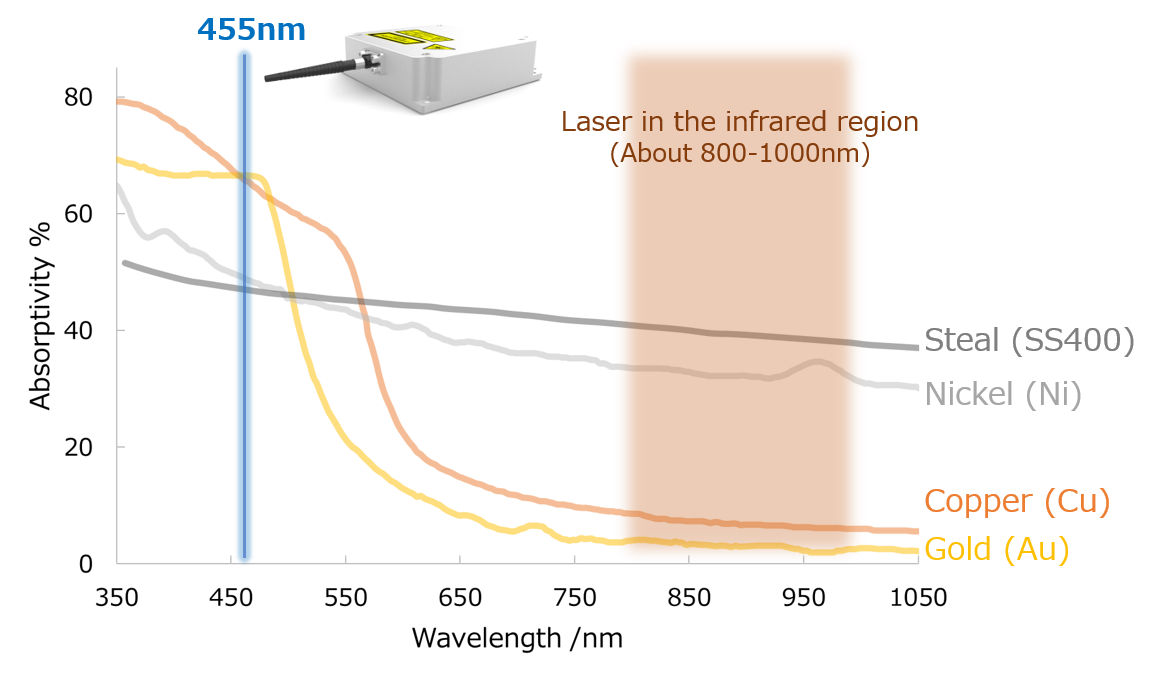

The laser heating process is used in a variety of fields due to its excellent non-contact and contamination-free features. In particular, a highly efficient high-power laser in the infrared region in the wavelength range of 800 to 1000nm is used commonly for the heating (melting, welding, and cutting) of metals. However, the very low absorptivity of metals in the infrared region (about 10 to 20%) and the reflection of much of the laser light reduce the energy efficiency. In addition, the reflected light heats the area around the processed region, damaging other materials and parts. This has been a challenge.

Meanwhile, in recent years, due to its high absorptivity of gold and copper and their alloys in the blue region in the wavelength range below 500nm (about 5 to 10 times the absorptivity in the infrared region), heating and processing processes using laser in the blue region are drawing attention from the viewpoints of energy efficiency improvement and damage reduction for the surrounding area.

■Spectral absorptivity of metals (gold, copper, nickel, and steal)

Laser in the blue region used in these applications has a high output power of about 10W to 1kW and is output using a fiber with a small diameter (about 100µm to 1mm) to ensure the efficiency of irradiation on the workpiece. In order to obtain a high output power, the light from multiple laser chips must be optically combined and coupled into the fiber. A large number of optical elements must be used to optically combine the light and accurate fine alignment is required, causing high costs. This has been another challenge.

In order to solve these challenges, Ushio has developed a blue laser module with 25W output from 200µm (0.22NA) core diameter fiber and 455nm wavelength by using its design technology acquired in its experience with the visual imaging field such as cinema projectors and its knowledge of the laser characteristics and optical combining technique, and the module can be used for a variety of manufacturing processes and easily mounted into equipment. Reduction of the number of optical elements used and a significant simplification of the adjustment process at assembly made it possible to reduce the size and weight and significantly reduce the costs.

This module can be mounted into equipment such as heating process, welding, and laser emitting equipment and is expected to be used widely in the heating process for high-reflectivity metals such as gold and copper, whose needs are growing as electronic equipment is becoming more sophisticated.

With its optical technology, Ushio will address industrial process challenges and contribute to industrial development.

■Product specifications

| Lasing wavelength (nm) | 455±5 |

|---|---|

| Fiber output (W) | ≥25 (25℃) |

| Fiber core / NA | 200µm to 0.22NA with SMA connector |

| Drive current and voltage | 3.0A (rated), 33V (typ.) |

| LD temperature control | Built-in thermistor in the module |

| Cooling surface | Module bottom surface |

| Housing dimensions (mm) | 119×130×34 |

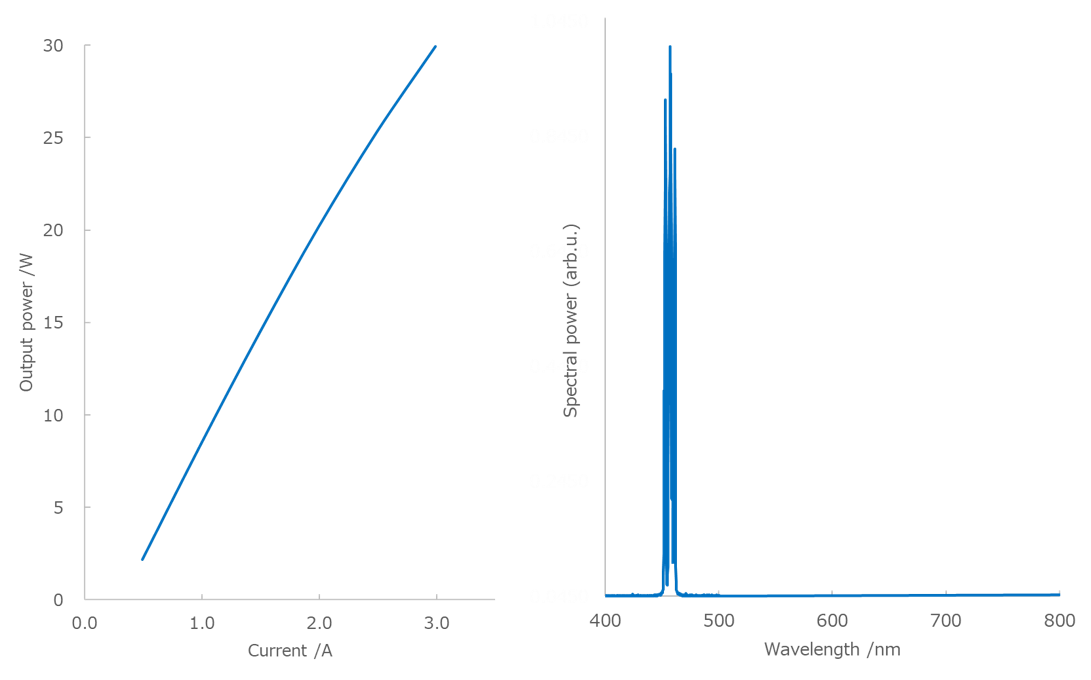

■Characteristic curves

Drive current – optical output curve (left) and output spectrum (right) characteristics examples