Projection Type

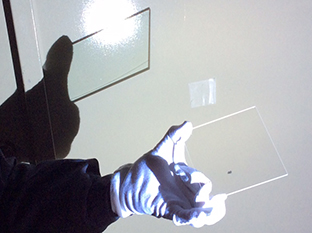

How Projection Type Works

Throwing light on permeable work piece such as glass and film, and the image projected on a screen is visually inspected.

This method reduces the effort required of operators since it minimizes.

This allows inspection results to be confirmed by multiple people at once, which contributes to benchmarks unification.

Projected Image

Filter Projection

Lamp Projection

Projection Result

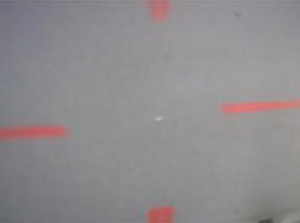

Examples of minute internal air pockets, such as bubbles, foam, voids or occlusions.

Air trapped in production workpieces appears on the screen as bright spots as in shown.

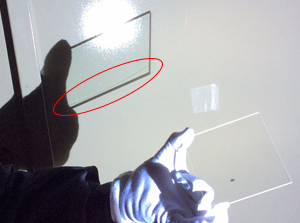

Examples of layer irregularities such as wrinkles, streaks and sink.

Irregularities in layers appears as wrinkles when materials such as plastic and glass are made into boards. Projection type is suitable for surface protection detects.

Examples of inside contamination and external defects such as scratches, and accretions.

Inside contamination and external scratches appear on the screen as shown.

Examples of wrinkles, streaks and sink.

Filter streaks are projected as shown.

Projection Lineup

- Contact

- TOP>

- Inspection Type: Projection Type