Liquid crystal display manufacturing process innovation 1: One drop fill (ODF)

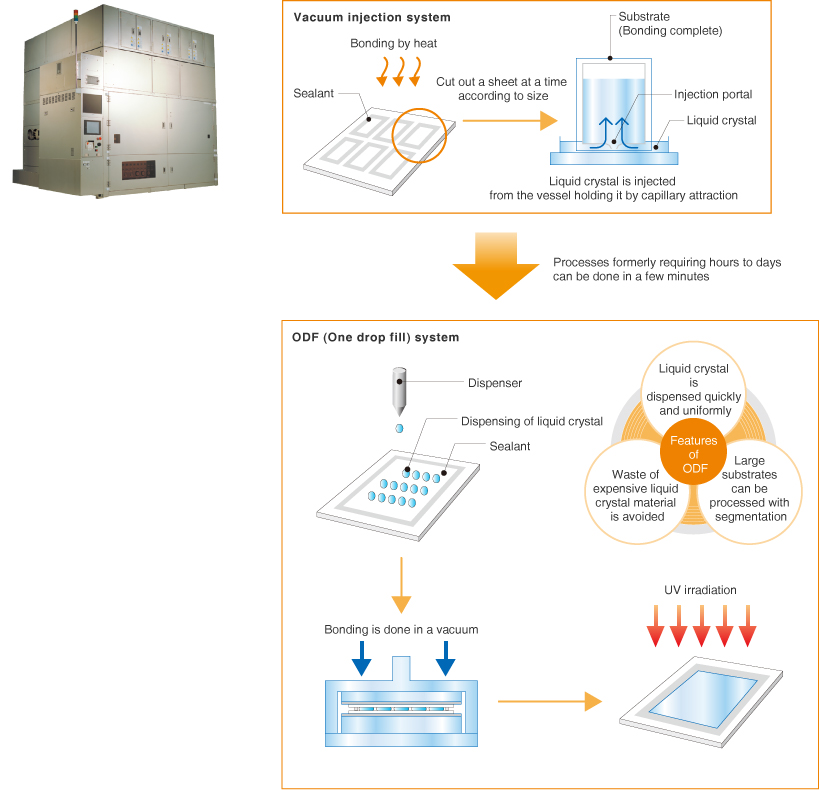

The UV photocuring equipment used for bonding of LCD panels makes full use of the technique of UV curing. In LCD panels, the liquid crystal is sealed between two sheets of glass, but the liquid crystal has a delicate chemical structure that cannot tolerate the use of heat to harden the adhesive used to bond the pieces of glass together. The method used to deal with this in the past was to bond the two pieces of glass together in advance, and then inject the liquid crystal through a gap left open for the purpose. However, the larger the LCD panel, the more difficult it becomes to quickly achieve uniform distribution of the liquid crystal between the sheets. To resolve this problem, an innovative method of dropping the liquid crystal directly onto one of the glass sheets and then bonding the second sheet of glass to the first came into use starting from about the year 2000. This new method is called the "one drop fill" (ODF) method. The fundamental technology on which the ODF method is based is UV curing, which allows rapid curing, low-temperature processing, and precision bonding. Today, UV irradiation units made by Ushio for bonding of LCD panels have a 70% world-wide market share.