Life Cycle Assessment Activities

Product LCA Information

Used in a broad range of fields, from industrial applications to illumination and business domains, Ushio's products create an environmental load on wide-ranging fronts throughout the entire product lifecycle. We are persisting with efforts to reduce the environmental load for society as a whole by devising various environmentally conscious countermeasures and utilizing numerical values at each stage of the product lifecycle to ascertain an overall profile of the environmental load. In this manner, the Ushio Group is striving to contribute to society through conserving the environment. As part of these efforts, we disclose Life Cycle Assessments (LCA) evaluation results for lamps widely used in offices and households, including discharge lamps and lighting power sources for projectors. The results of these evaluations are utilized for improvements in product design and manufacturing processes as well as for in-house environmental education.

* An acronym for Life Cycle Assessments, LCA is a method for quantitatively estimating and assessing resource and energy used by products and the environmental load generated by these products throughout the entire product lifecycle—from raw materials procurement to manufacture, usage, recycling, and final disposal—as well as assessing the latent impact of these products during the same lifecycle.

High-Intensity Discharge Lamp for Data Projectors (NSH Lamp) and Lighting Supply Source

High-Intensity Discharge Lamp for Data Projectors (NSH Lamp)

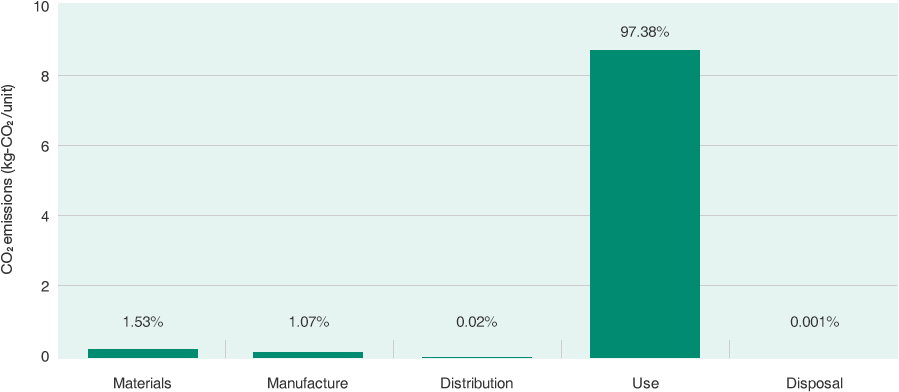

In this case example, Ushio calculated CO2 emissions for one lamp at each stage of the product lifecycle. We learned that CO2 emissions during lamp usage account for approximately 98% of total CO2 emitted during the entire product lifecycle, mainly resulting from electric power consumption. The next largest proportion of CO2 emissions is from materials used in the lamp, which account for about 1.5% of emissions, mainly the reflector, front glass, and other glass materials. Our assessments thus reveal that CO2 emissions are particularly large during the usage stage. The development of energy-conserving lamps is therefore crucial as an improvement measure.

Product evaluated: High-intensity discharge lamp for data projectors (Direct current lighting 300W)

Period of usage: 1,500 hours

Product flow: Materials →manufacturing (production plant) → distribution → usage → disposal

CO2 Emissions by Life Cycle Stage

Lamp Product Safety

The categories of chemical substance contained in the above-mentioned lamps are listed on a material safety data sheet (SDS). To ensure safe and proper product handling, the names of substances contained in products as well as information on the hazards and toxicity of these substances, precautions in handling, and information on environmental impact are contained on the SDS.

For inquiries regarding SDS, please contact Ushio's sales representatives.

Lighting Power Source for High-Intensity Discharge Lamp for Data Projectors

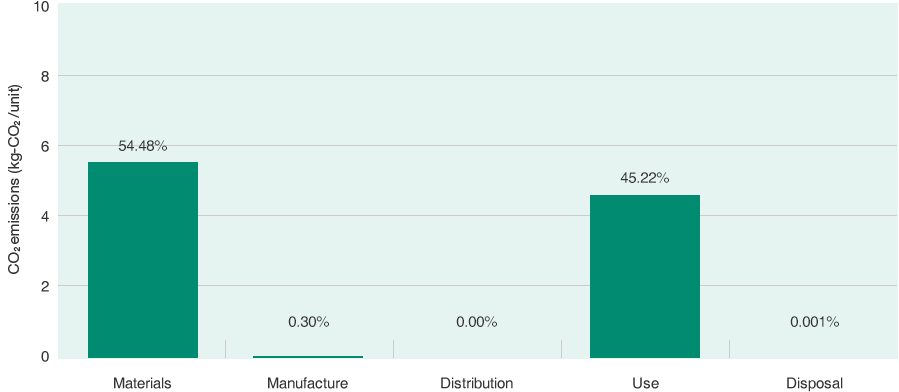

In this case example, Ushio calculated CO2 emissions for a lighting power source at each stage of the product lifecycle. We learned that CO2 emissions occurring at the stage of the materials used in the power source accounted for around 54% of the total CO2 emitted during the entire product lifecycle. Moreover, these materials were mainly transistors, diodes, and other semiconductor device materials. The stage responsible for the next largest proportion of CO2 emissions is the stage of usage, which accounts for about 45% of the total emissions, mainly resulting from electricity loss. The electricity loss at this stage of usage is calculated by converting the load loss into CO2 emissions. Our assessments thus reveal that particularly large CO2 emissions result from materials used and from the usage stage. Improvement measures include selecting semiconductor elemental devices with a lower environmental load, reducing the number of semiconductor elemental devices that cause large environmental loads by improving power source circuits, and raising the efficiency of lighting power sources by developing energy-saving technologies.

Product evaluated: Lighting power source for high-intensity discharge lamp for data projectors (AC lamp NSHA 230W)

Period of usage: 1,750 hours (3.5 hours per day for 100 days per year over five years: based on the Japan Environmental Management Association for Industry's EcoLeaf Program, Product Specification Criteria (PSC) for data projectors, No. AG-03)

Product flow: Materials →manufacturing (production plant) → distribution → usage → disposal

Volume of CO2 Emissions at Each Stage of the Product Lifecycle

* This power source is manufactured overseas and thus we have excluded the shipping stage.

* For the same reason, we have used values related to production in Japan for CO2 conversion unit values.