Conserving Resources

Initiatives for Water Usage Reduction

The countries and regions where the Ushio Group is based, both in Japan and overseas, include various areas where droughts affect water intake, and areas where water is available but access to safe water is limited due to sanitation issues.

The same attitude of taking good care of water resources needed around the world is required of companies. We also recognizes the need to properly confront, understand, and manage water.

We began by analyzing the water consumption and applications of the entire group. As we entered the semiconductor-related manufacturing business, a sharp increase in water consumption was recognized.

In addition, with some exceptions, we have already made progress in installation of recycling water systems in major sites, and we have found that there is little room for reduction. Accordingly, we have set KPIs based on the results of various measures considered.

As one of our material issues, starting in fiscal 2021, we continue our efforts to conserve water resource as a priority issue, as well as to work to respond to water risks.

Plans for Water Resource Reduction in fiscal 2021 and beyond

| Key Issue as 4th Management Focus Plan for FY2021 |

Reduce USHIO Group's water usage by 0.5% compared to fiscal 2019. * |

|---|---|

| Key Issue as 4th Management Focus Long-Term Targets |

Long-term target: Reduce water usage by 10% by fiscal 2030 compared to fiscal 2019 |

Note: Water resource reduction initiatives in the 6th Environmental Action Plan were also evaluated as important issues in the materiality identification.

Therefore, we will continue to work on them as one of the themes of Focus 4 of the management from FY2021.

Initiatives for Reduce Waste

At Ushio, waste processing information is shared between Group companies and business sites in Japan. In addition, initiatives such as recycling have been strengthened, aiming to curb total waste emissions.

Plans for Water Resource Reduction in fiscal 2021 and beyond

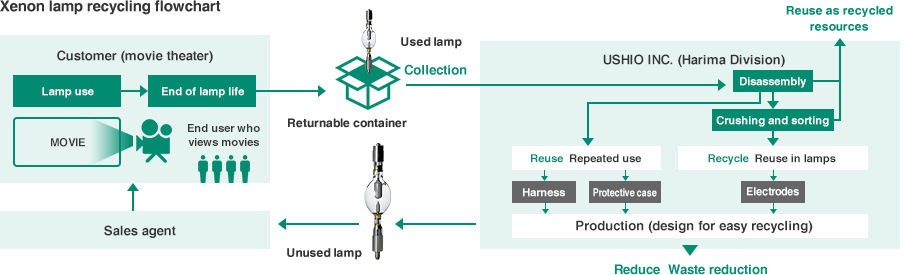

A recycling program was started in 2007 for super high-pressure UV lamps for semiconductor and LCD exposure operations. We have since also launched a recycling initiative for xenon lamps for cinema projection equipment. Xenon lamps contain tungsten, one of the rare metals. Lamps collected by the program are turned into products or returned to society through 3R activities.

Reducing the Amount of Harmful Chemical Substances Used

In fiscal 2011, our efforts to reduce the amount of harmful chemical substances used included conducting a survey of the status of usage at each business site. Based on the survey findings, we decided to reduce our use of volatile organic chemicals (VOCs) in line with the recommendation of four electrical machinery and electronics associations in Japan. Since fiscal 2012, we have been reducing the consumption of VOCs by means of reviewing our production facilities.

Initiatives at the Harima Division

The Harima Plant is working to reduce the use of chloroform, which may cause pollution due to air release that occurs in our lamp manufacturing process. Specifically, we introduced two sealed automatic equipment, reduced the opening of the hood, and consolidated facilities using chloroform from two tools to one. However, in recent years, the number of productions has been increasing and the size of products has been increasing. As a result, the volume of use has been increasing more than the amount generated by reduction efforts, we are further strengthening our efforts to this end.

Furthermore, as regulations on chemical substances have become stricter year by year, we expect to reduce the use of chemical pharmaceuticals other than chloroform by reducing the size of hood openings and reviewing the amount of wind drainage when changing the layout, and also by reducing the amount of evaporation.

In addition, in order to create a safer work environment, we are taking an initiative in eliminating hazardous substances by examining chemical pharmaceuticals with a high-level risk assessment for chemical substances as substitutes.

Amounts of Chloroform Usage

| Fiscal 2017 | Fiscal 2018 | Fiscal 2019 | Fiscal 2020 |

|---|---|---|---|

| 8.7 t | 9.3 t | 9.0 t | 6.9 t |

In addition, Ushio makes a concerted effort to act appropriately, including by using alternatives to other chemical substances.

Initiatives at the Gotemba Division

Since 2017, we have been reviewing risk assessments by visualizing chemical substances through monitoring the amount of chemical substances used once every 6 months and by patrolling chemical substance storage sites every month.

In order to prevent the leak of hazardous substances into rivers and underground infiltration, we constantly monitor the pH and fluorine concentration when releasing them from our fluorine wastewater treatment facilities. To deal with an event of an abnormal pH and fluorine concentration, we have introduced a facility that stops it.

As for underground permeation, all pipes through which hazardous substances flow are double-walled so that anomalies in the pipes can be detected immediately without burying them as much as possible.

In addition to installing a dike in the place where hazardous substances are stored, and we put a coating on the concrete surface to prevent permeation so that underground permeation does not occur.