光技術情報誌「ライトエッジ」No.40(2014年3月発行)

The 10th Conference on Lasers and Electro-Optics Pacific Rim

(CLEO-PR 2013)

Micro-dispensing for three-dimensional direct

fabrication of laser waveguides

Noboru Hirakawa, Hiroyuki Kubota, Hiroaki Yoshioka

Noriyasu Tarumi*, Yoshio Kagebayashi* and Yuji Oki

Dept. of Electronics, School of I.S.E.E. Kyushu University,

744-WEST2 Motooka, Nishi-ku, Fukuoka 819-0395, Japan

* USHIO INC., 6409 Motoishikawa-cho, Aoba-ku, Yokohama 225-0004, Japan

Abstract

Direct drawing of laser-waveguide with width of 20µm on unflat surface was demonstrated by using micro-dispensing technique. Highly viscous prepolymers form high aspect ratios such as 18µm width and 7 µm height with one time dispensing.

1. Introduction

Solid state dye lasers are tunable coherent light sources that can provide low-end photon cost [1-4]. Recently, our laboratory has focused on print-like fabrication of solid-state-laser systems to realize a 2D surface integrated coherent light source. On-demand fabrication technique is effective to integrate lasers with other applications such as optofluidic chips, micro well, on optical fiber applications , and so on [ 5 ] . We suggested “prepolymer dispensing direct drawing” as an on-demand and stackable fabrication technique for vertical single mode polymeric waveguide lasers. It easily mounts the waveguide laser cavities on any surface such as curved and narrow. Recently, we have tried to fabricate DFB lasers on surface of multiple-mode polymeric optical fibers (POFs) [6]. Solid state dye lasers on POF showed single wavelength emission with first ordered distributed feedback structure and waveguide of vertical single (3µm) and horizontal multiple (100µm) propagation mode.

In this report we tried fine drawing with 20µm width to attain optical circuit drawing on POF.

2. Fabrication process by micro-dispensing

At first, the clad polymer coating removed partially from polymethylmethacrylate (PMMA) polymeric optical fiber (Mitsubishi, SK-20). The core diameter was 480µm and its refractive index was 1.486. Subsequently, the laser waveguides were drawn by the highly-accurate dispenser (Musashi Engineering, ML-808FXcom). The dispensing needle was changed from a normal SUS needle (100µm inner diameter (i.d)) to a ceramic micro needle (FN-0.02??, 20µm i.d and 50µm outer diameter (o.d)). Normally, the working distance between the needle point and the substrate surface (POF core surface) must be kept about 1~3 times of the i. d. of the needle. The prepolymer was prepared by polymerizing mixture of MMA and 2-hydroxyethylmethacrylate (HEMA), and half-polymerized prepolymers were mixed with the laser dye. To avoid spreading the prepolymers to the o.d. of the needle, the cleaning protocol must be optimized using a jet of organic solvent. The drawing parameter for narrow drawing was the viscosity of the prepolymers, the extrac ting pressure, the working distance and the drawing velocity. We also developed rotatable POF holders using motorized stages. The simultaneous drawing and rotation can obtain three-dimensional drawing on the cylindrical surface of POFs.

3. Experiments and results

3.1 20µm width waveguide profile

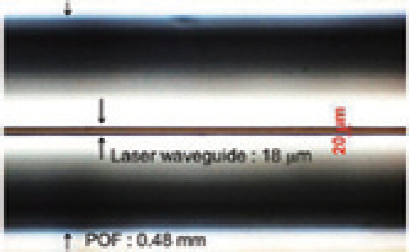

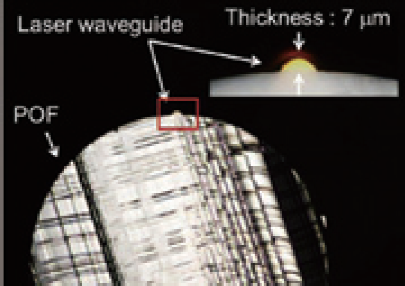

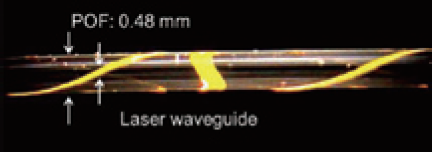

The laser waveguide material was p (MMA80:HEMA20) doped with Rhodamine590 in the concentration of 2mM. The refractive index was tuned to 1.496. The prepolymer with viscosity of 1000mPa·sec was drawn with the working distance lower than 10µm, and the width of the waveguide was almost equal to i.d of the needle. Fig.1 shows microscopic image of the top view of laser on the POF. The waveguide width was approximately 18µm. The length of 10mm could be drawn with unique width. Fig.2 shows the cross section profile. The waveguide thickness was about 7µm was obtained. The aspect ratio of 7:18 was 10 times higher than that of previous our work ( 3µm:100µm)

Fig. 1 Laser waveguide of width 18µm on POF

Fig. 2 cross-sectional surface of laser waveguide on POF

3.2 DFB laser properties

A passively Q-switched DPSS Nd: YAG laser (532nm, 10µJ) was used as a pumping source, and its output beam was coupled to an end side of the POF.

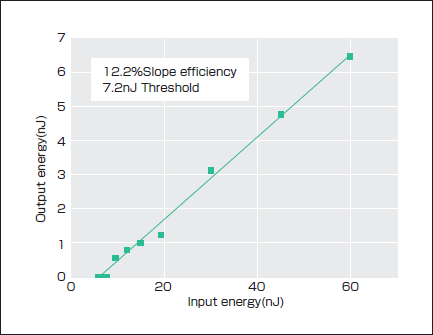

When the propagating pumping beam pulse reached to the DFB laser mounting point, the propagating pump-beam was partially coupled to the DFB laser waveguide with leaky propagation mode. Since the tapered couplings were fabricated on the both ends of the waveguide, the laser output can be coupled to the POF in forward and backward directions. The DFB laser output was monitored in the forward direction. The slope efficiency can be estimated as 12.2%, and the laser threshold around 7.2nJ was estimated.

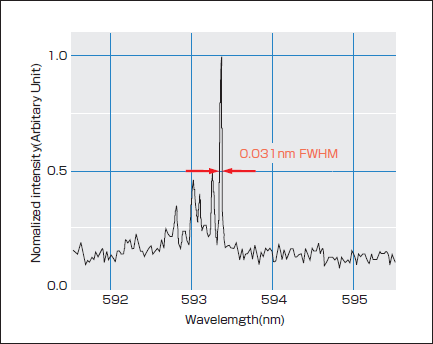

The output spectrum was monitored as shown in Fig. 4. It seemed that the narrow waveguide fabrication provided vertically and horizontally hybrid propagation modes. So the fine spectral structure was observed. One of the modes shows bandwidth of 0.031nmFWHM, and it is half of the previous results. However, the multiple complex mode structure shows like spectral background. To improve this multiple fine modes to single peak mode, we have to reduce higher order mode by designing refractive index structure.

Fig. 3 laser input output profile based on the actually absorbed pumping energy.

Fig. 4 laser spectrum of laser waveguide of width 20µm

3.3 Three-dimensional direct mounting of laser

On the other hand, spiral laser waveguide on POF was demonstrated as a first sample of three dimensional fabrications. The rotational control equipment was introduced. It could be controlled in arbitrary angle and speed, the higher flexible three-dimensional waveguide was fabricated by using it together with the dispensercontrol.

As shown as Fig.5 a spiral laser waveguide on POF was demonstrated. It was shown that three-dimensional waveguide can be fabricated in width of 40µm on a cylindrical surface. Moreover various-shaped laser waveguides can be fabricated on POF by using this equipment. This waveguide is considered in the use a samp of whispering-gallery or continual twist sensor. This waveguide is considered in the use as amp of whispering-gallery or continual twist sensor.

Fig. 5 spiral laser waveguide on POF

4. Conclusion

We demonstrated laser waveguide of width 18µm and three-dimensional direct mounting of laser waveguide on POF by micro-dispensing technique. Spectrum profile of multiple modes was observed, but bandwidth of 0.031nmFWHM was obtained. The laser threshold about 7.2nJ was also estimated. The spirally mounted laser waveguide was also demonstrated as an example of three dimensional fabrications.

Acknowledgement

This study was supported by JST Feasibility Study (FS) Seed Excavation ‒A Program, Japan.