Projection Lithography Technology

Ushio's Projection Lithography Technology

Total solutions ranging from light sources to optics and from transport technology

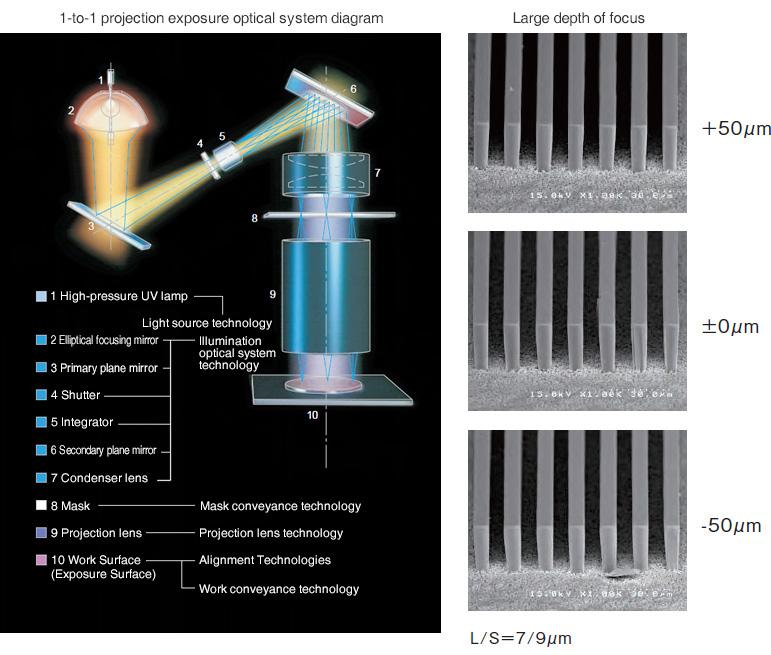

Ushio's full field projection lithography tools use specially developed high-output lamps together with projection lithography to prevent mask damage and enables reduced mask patterns along with build-up and high resolution stacking of multi-layer patterns.

We introduce Ushio's element technology for large area projection lithography suitable with all sorts of substrates, such as glass boards, ceramic boards, roll boards, and printed circuit boards (PCBs).

-

Light Source Technology

-

Optical Technology for Illumination

-

Projection Lens Technology

-

Alignment Technology

-

Mask Transport Technology

-

Work Transport Technology

Light Source Technology

Design optimized especially for lithography tools

Ushio: A light source maker providing high energy, high stability ultraviolet light sources (UV lamps) for a wide range of lithography tools, such as semiconductor and LCD steppers.

With the UX Series as well, lithography tool and light source development are launched simultaneously, so specially designed light sources ensure that the characteristics of optical systems of all lithography tools are fully utilized.

Optical Technology for Illumination

Changing light to reach the ideal

The illumination optical system efficiently collects light emitted by the lamp and acts to irradiate the mask with highly uniform, highly collimated illumination. The special coating applied to mirrors work to select the exposure wavelength and cut heat rays.

The growth of Ushio's illumination optical system technology began with the development in 1960 of a a high-tech solar simulator employing advanced optics for use in a space chamber. Since then, Ushio has provided illumination optical systems for many lithography tools used in the production of semiconductors and LCDs, and in the process has brought such systems to increasing levels of refinement.

The illumination optical system employed in the UX Series is the outcome of all that accumulated know-how, and is available in a wide variety of variations with different lamp outputs and exposure wavelengths, providing the ideal light according to process.

Projection Lens Technology

Making it possible extreme focal depth and avoidance of mask damage

Ushio's attention was attracted to the projection exposure system because it does not require contact between the mask and work, making it possible to avoid mask damage, and has successfully developed projection lenses that achieve formerly unattainable low distortion over a wide area.

This proprietary Ushio projection lens comprises a low-distortion lens line-up that can stretch the lithography area to a maximum diameter of 355 mm or achieve resolving power of up to 2µm L/S. The optical design developed for this series of projection lenses is optimized for a variety of needs that accommodates all sorts of exposure areas and resolutions while maintaining great focal depth.

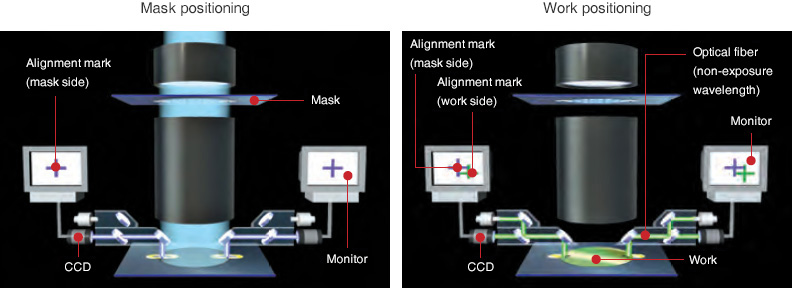

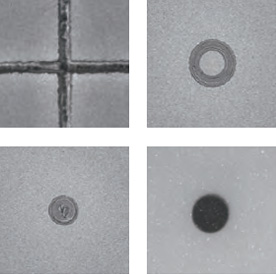

Alignment Technology

Achieving high-precision positioning

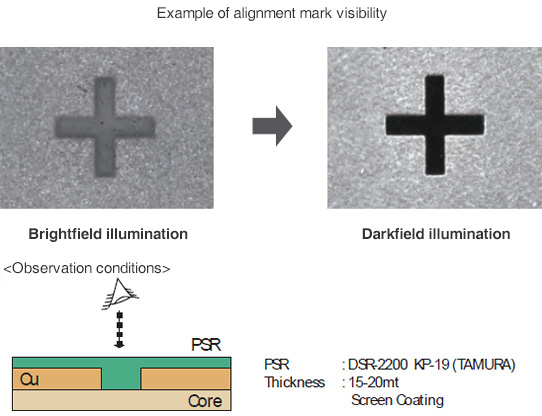

Uses proprietary TTL non-exposure wavelength alignment system. In this system, the alignment marks of the mask and the workpiece are individually detected and fixed on xy coordinate axes through image processing. Characteristics of the system are as follows.

TTL Non-Exposure Wavelength Alignment

Work piece identification is easily accomplished through individual observation of the mask and workpiece, even for small masks that have been painted with chromium across their entire surface.

Further, there is no reduction contrast due to observation through the mask, enabling alignment with clear marks.

Even if mark contrast is low due to influence of the underlayer, visibility can be improved by selection of the illumination method (bright field or dark field illumination) and wavelength.

Adjustment of Projection Magnification

Expansion or contraction of the pattern accompanying substrate expansion/contraction is detected and the projection magnification is automatically adjusted by up to ±0.1%. This makes it possible to achieve perfect registration even with work where overlay exposures are subject to great expansion or contraction.

Pattern Matching System

In cases where there are no particular alignment marks, alignment can be achieved through image recognition by registering a variety of wiring patterns. Also, a variety of alignment algorithms are available for selection to suit different types of alignment marks.

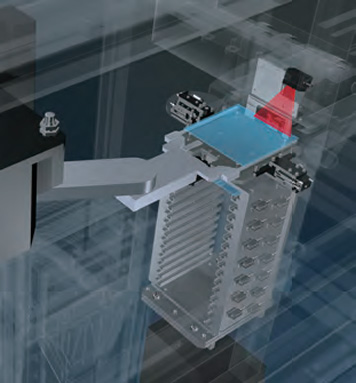

Mask Transport Technology

With the addition of an optional mask loader and mask library of Ushio's own design, work changeovers can be accomplished without time loss.

Moreover, the automatic mask transport function contributes to reduction of human errors that result in mask damage or incorrect work type, and the ability to move and mount masks in a mask case prevents adhesion of particles.

Work Transport Technology

A variety of high-precision transport systems are available to accommodate work items such as Si wafers, flexible substrates, and printed circuit boards.

Further, stages that accommodate batch exposure utilizing a wide exposure field and with step & repeat exposure for larger work areas provides support for efficient and stable processing for all sorts of needs.