Ushio in Life

Deliver colorful image by liquid crystal display

- Comfort / Convenience

- Optical Equipment

Products equipped with LCD panels, such as smartphones, PCs, and TVs, have become indispensable in various aspects of life.

LCD panels are becoming increasingly sophisticated, bright, vibrant, and convenient. Ushio Inc.’s expertise in light contributes to this evolution.

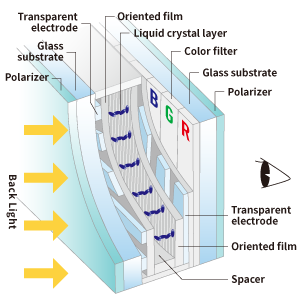

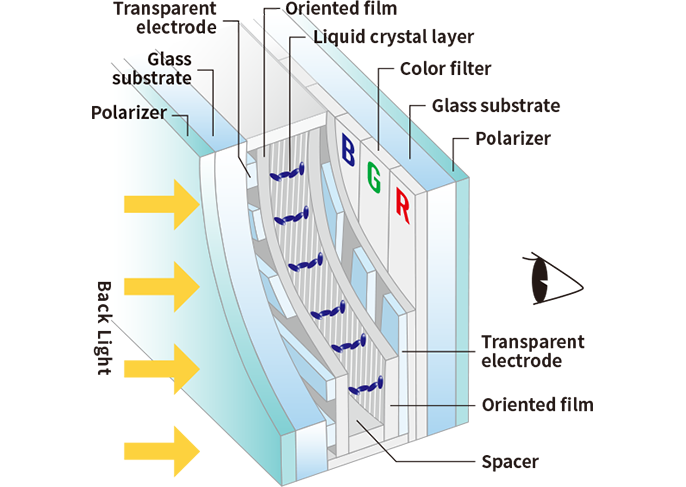

LCD panels comprise various components that are stacked like a sandwich, including parts that control brightness; color filters that display colors by filtering red (R), green (G), and blue (B), respectively; backlights that illuminate and brighten displays from behind; and membranes that align liquid crystal molecules.

The liquid crystal molecules in LCD panels play a vital role in enhancing the beauty and speed of images. Optimally arranging and controlling these molecules is an important process that determines the performance of LCD panels. Since liquid crystal molecules have the property of sticking together like crystals, they are in a disordered state if left alone. By aligning the molecules correctly in any direction, they react to the light from the backlight, enabling them to express the movement and colors of an image. Traditionally, liquid crystal molecules have been aligned in structures, but Ushio has developed a new energy-saving technology that achieves even more beautiful images and aligns the molecules neatly by irradiating them with a special light.

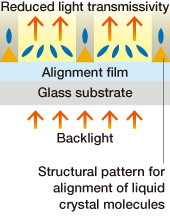

Liquid crystal molecules are aligned with a structural pattern

Structural pattern used for liquid crystal alignment impedes light transmission, making images darker and reducing image quality. Increasing the brightness requires a larger backlight, which increases display size. This method also leaves irregularities in liquid crystal ordering and angle, reducing response speed.

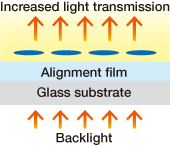

Ushio’s optical alignment technology

Liquid crystal molecules regularly aligned in one direction without structural patterns by means of irradiation with special light. Improved light transmission reduces power requirements and achieves greater alignment regularity for improved contrast.

It is also important to support high pixel counts in order to view high-resolution images on LCD panels. A single pixel in an LCD display is made up of three colors (RGB), with light passing through each color. The switch function for adjusting this light is provided by a substrate called a thin-film transistor (TFT). In the 8K Ultra HD (UHD) that can be seen in TVs and other devices, the total number TFTs attached to each pixel is 33 million multiplied by each RGB color, amounting to over 99 million. By controlling these TFTs, we are able to project high-resolution images. We use a lithography tool to manufacture these microscopic TFTs. TFTs are made by using a lithography tool to irradiate and transfer the original plate of a TFT circuit pattern. The UV lamps used in these lithography tools also utilize Ushio’s technology.

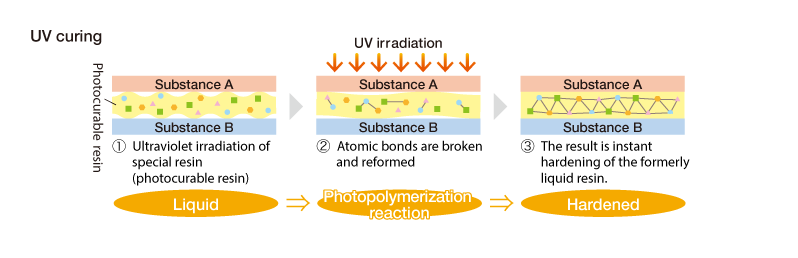

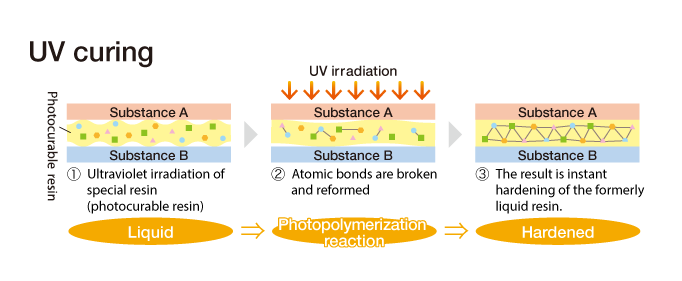

Furthermore, we have not only achieved the manufacture of high-performance LCD panels. Ushio’s expertise in light technology also contributes to even more efficient manufacturing. We are making significant contributions to the manufacture of LCD panels for devices such as LCD TVs, smartphones, and monitors by reducing the manufacturing time to one-tenth that of conventional processes for laminating glass substrates and encapsulating LCD through the use of UV curing technology.

Ushio is delivering beautiful images to everyone through its LCD panels.

Enjoy more vivid and exciting moments anytime, anywhere, on a daily basis, with realistic, bright photos and videos of your memories, and see people you cannot meet in person as if they were before your eyes.