Ushio in Life

Contribute to evolution of semiconductor technology to enrich our life

- Comfort / Convenience

- Optical Equipment

Semiconductors are used not only to support the social infrastructure of the internet and communication networks but also in appliances such as washing machines and air conditioners, as well as smartphones, PCs, ATMs, automobiles, and airplanes. While we do not touch them directly ourselves, they are an indispensable part of our lives. Going forward, the evolution of semiconductors will be vital for cutting-edge technologies, such as advances in AI technology and automated driving.

Ushio is contributing to this evolution through its expertise in light.

Semiconductors are small substrates (chips) that store and process large amounts of information. Electrical components that comprise hundreds of electronic circuits, such as integrated circuits (ICs), are mounted on semiconductor materials that act as both conductors and insulators.

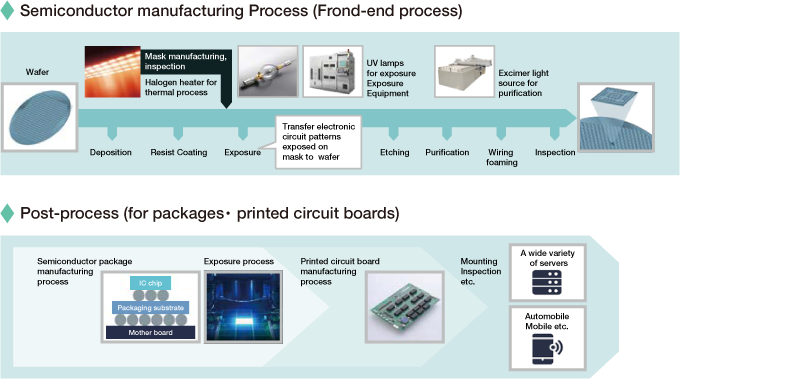

“Light” in semiconductor manufacturing process

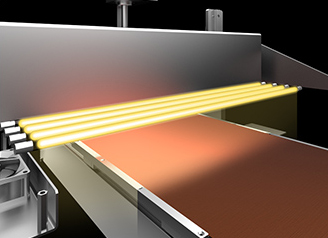

Heating with light

In semiconductor manufacturing process, waver thermal process is highly critical. As thermal treatments, there are several ways such as slow thermal control by electric furnace, and placing on the hot plate, Ushio proposes quick heating treatment in non-contact manner using light. For example, flash lamp is extreme instant heating treatment, which only takes 0.001 seconds to heat up to 1000℃. It allows to expose φ300mm waver in one shot, avoid the heat effect to the unnecessary parts, and contributes to manufacture fine devices as essential light technology.

Drawing with light

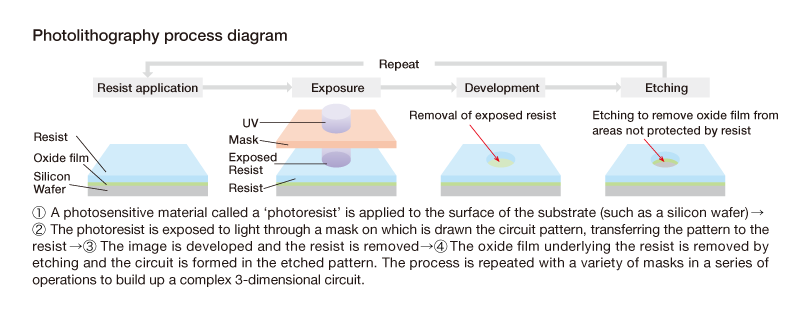

Our expertise in light technology is also important when transferring circuit patterns to the membrane of wafers. If conductive materials, such as aluminum and copper, are embedded into the uneven surface of the circuit pattern that has been transferred to the substrate, they become the wiring, or the path for the electricity. The thinner this wiring is, the smaller we can make electrical components, meaning that chips can become more compact, multifunctional, and high performance. The width of the wiring is determined by light wavelength. We have successfully developed various elemental technologies at Ushio and combined them to create an optimal balance. These technologies include optical technology, which provides stable and efficient irradiation at high energy levels on a specific wavelength; [transport/conveyance] technology, which [supports/is compatible with] a variety of materials, such as hard glass and thin film; alignment technology, which regulates the positioning of light irradiation; and software technology, which controls all of these processes.

High Pressure UV Lamp

Direct Imaging Exposure System

Large Field Stepper UX-5 series UX-7 series

Performing purification with light

For semiconductors, which are manufactured at a microscopic level that cannot be seen with the naked eye, molecular-level particles and organic matter can cause imperfections. For semiconductor manufacturing, the purification process is extremely important. Because purification with chemical may cause the damage to base materials, we have enabled the purification of damage sensitive components by breaking down organics with UV light, without using water or solvents and without damaging the base materials.

Conducting inspections with light

It is impossible to inspect circuits for something as miniscule as a semiconductor by sight. Using light, rather than the naked eye, we inspect whether there are any issues with semiconductor device circuits through lighting technology that accurately illuminates the objects being tested; image analysis technology that captures, processes, and treats reflected light with high precision; and high-speed processing technology. The precision of the inspection is at the same level as looking for 10 coins within a 600 kilometer diameter area between Tokyo and Aomori and finding all of them in under 60 minutes.

EUV Light source for Mask Inspection

In order to create components that are required to evolve on a daily basis, the manufacturing process must also constantly evolve. Ushio uses light to support highly efficient components, which we use daily but cannot see or touch.