Ushio Introduces a UV-LED Drying Device for Rotary Printing Machines

Downsized to 120mmx120mm

Ushio Inc. (Head Office: Tokyo, CEO: Koji Naito, hereinafter “Ushio”) announces that it has introduced the “UniJet W Series,” a new UV-LED drying device for rotary printing machines as part of the “UniJet Series” of high-performance drying devices.

In the area of sticker label printing where rotary printing machines are used, demand for labels printed on thin films is increasing in order to reduce the environmental load and the total cost of ownership (TCO). However, since thin films are easily damaged by heat, the conventional UV lamps in the UV drying devices have started being replaced with UV-LEDs due to lower heat generation.

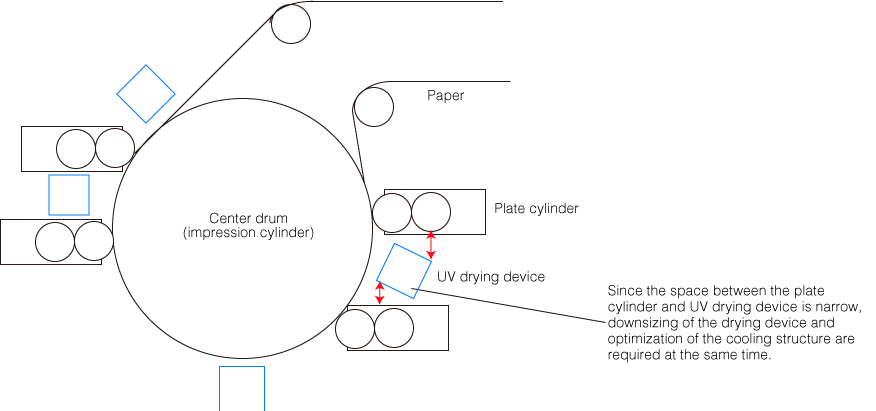

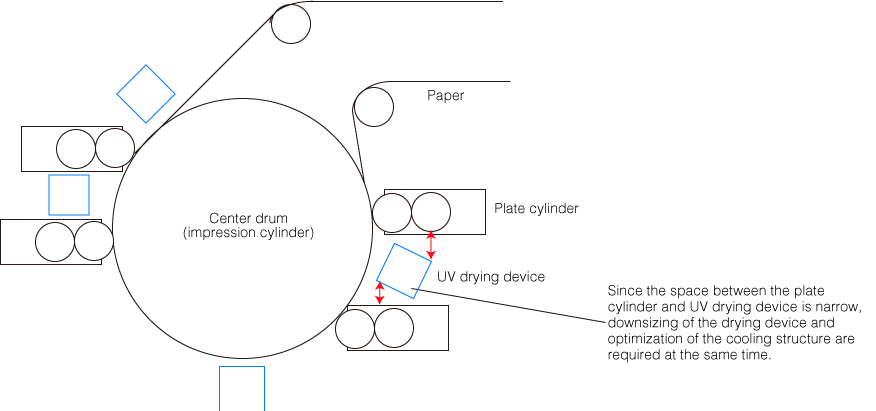

However, since the installation space of the UV drying device is limited in rotary printing machines, in particular in a center drum type (see the figure below) compared to other printing machines, downsizing of the drying device and optimization of the air inlet and outlet are required for the UV-LED drying device to suit the rotary printing machines (where the UV lamps are used as a true cure for rotary printing machines), but it has been difficult to achieve the downsizing of the drying device and the optimization of the cooling method and air inlet/outlet flow at the same time.

Ushio has solved this problem by achieving a higher dose energy than that of the previous air cooling method by combining the LED optical design technology*1 acquired as a lighting manufacturer with the thermal fluid design technology*1, and at the same time, downsizing the drying device to 120mmx120mm and designing a cooling structure with an air inlet at the front and an air outlet at the rear which has been optimized for the printing machine design and the operator environment.

This enables replacing the existing UV lamp unit with a UV-LED even for a center drum type printing machine.

Ushio will continue leveraging its expertise in light to reduce the TCO and increase the quality in the printing industry.

■ Features

(1) Downsized to the industry’s smallest dimensions of 120mmx120mm

Downsizing was achieved using Ushio’s proprietary LED high-density mounting technology

(2) Achieving a structure with an air inlet at the front (on the operator side) and an air outlet at the rear (on the gear side) which is the same structure as that of the UV lamp unit

Achieved an air inlet and outlet structure optimized for rotary printing machines

(3) There is a choice of air-cooling fan or duct for the exhaust method

Achieved energy conservation and easy installation of the air-conditioning equipment

(4) Maintaining the illuminance necessary and sufficient for rotary printing machines

Ushio’s proprietary optical design enabled achieving dose energy that is sufficient for sticker label printing (300mJ/cm2 *2)

■ Specifications

■ Product Image

In the area of sticker label printing where rotary printing machines are used, demand for labels printed on thin films is increasing in order to reduce the environmental load and the total cost of ownership (TCO). However, since thin films are easily damaged by heat, the conventional UV lamps in the UV drying devices have started being replaced with UV-LEDs due to lower heat generation.

However, since the installation space of the UV drying device is limited in rotary printing machines, in particular in a center drum type (see the figure below) compared to other printing machines, downsizing of the drying device and optimization of the air inlet and outlet are required for the UV-LED drying device to suit the rotary printing machines (where the UV lamps are used as a true cure for rotary printing machines), but it has been difficult to achieve the downsizing of the drying device and the optimization of the cooling method and air inlet/outlet flow at the same time.

Ushio has solved this problem by achieving a higher dose energy than that of the previous air cooling method by combining the LED optical design technology*1 acquired as a lighting manufacturer with the thermal fluid design technology*1, and at the same time, downsizing the drying device to 120mmx120mm and designing a cooling structure with an air inlet at the front and an air outlet at the rear which has been optimized for the printing machine design and the operator environment.

This enables replacing the existing UV lamp unit with a UV-LED even for a center drum type printing machine.

Ushio will continue leveraging its expertise in light to reduce the TCO and increase the quality in the printing industry.

| *1 A patent has been applied for in respect to this product. |

■ Features

(1) Downsized to the industry’s smallest dimensions of 120mmx120mm

Downsizing was achieved using Ushio’s proprietary LED high-density mounting technology

(2) Achieving a structure with an air inlet at the front (on the operator side) and an air outlet at the rear (on the gear side) which is the same structure as that of the UV lamp unit

Achieved an air inlet and outlet structure optimized for rotary printing machines

(3) There is a choice of air-cooling fan or duct for the exhaust method

Achieved energy conservation and easy installation of the air-conditioning equipment

(4) Maintaining the illuminance necessary and sufficient for rotary printing machines

Ushio’s proprietary optical design enabled achieving dose energy that is sufficient for sticker label printing (300mJ/cm2 *2)

| *2 At a printing speed of 50m/min |

■ Specifications

| Dimensions | 468.9mm×120mm×120mm |

|---|---|

| Wavelength | 385nm / 395nm |

| Dose energy | 300mJ/cm2 |

| Input power | 180V to 240V AC,20A, single-phase |

| Dimming | 10 to 100% |

■ Product Image