光技術情報誌「ライトエッジ」No.31

2007.5 LS-11(11th Int'l Symp. on the Science and Technology of Light Sources)

(2008年10月)

Current waveform optimization

of AC-operated short arc ultra high pressure mercury lamps

for projection applications

T. Tsukamoto, Y. Horikawa, A. Sugitani

NSH-Business Unit, Lamp Company, USHIO INC., 1194, Sazuchi, Bessho-cho, Himeji, Hyogo 671-0224, Japan

Contact : t.tsukamoto@ushio.co.jp

ABSTRACT

Maintenance of the tip at the front end of tungsten electrodes in AC-operated ultra high pressure mercury lamps is very important to keep sufficient and stabilized luminous flux. The current waveform optimization is necessary for long lamp life. New driving scheme "Udrive" with unique current waveform has been developed. The driving scheme is composed of the high frequency square-waveform predominantly to reduce the change of tip temperature and intermittently inserted lower frequency for adjusting the shape of the tip. The mechanisms of good maintenance of the tip with "Udrive" are clarified.

INTRODUCTION

The short arc ultra high pressure mercury lamp is one of the standard light sources for projection applications. Extremely high operating pressure around 200atm is required to obtain high luminance and good spectrum for projection[1].

A tip at the front end of tungsten electrode plays an important role in increasing the luminance by constriction of the arc spot. Moreover, since the tip isolates arc spot from the electrode body, the significant part of the light is able to escape from the bulb without being blocked by the electrode body. Consequently, higher luminance efficiency can be obtained on projectors. In order to maintain the electrode tip, the lamp driver with superimposed pulses on the square-waveform has been developed by Philips[1]. Independently, we have developed the new lamp driver with frequency modulated current waveform "Udrive"[2].

In this paper, the effectiveness of "Udrive" is described in terms of electrode temperature depending on current waveform.

TIP SIZE AND SHAPE WITH SIMPLE SQUARE-WAVEFORM OPERATION

When an AC lamp is operating, the electrode is heated up by collected electrons during anode phase and cooled by emission of electrons during cathode phase. It has been described that the tip is generated by the deposition of back-transported tungsten ions by electric field[1].

Moreover, we found that the surface energy minimization of the molten tip during repeated melting and solidification cycles plays a crucial role in generating and in upthrusting the tip. Even at the front end of the anode of DC operated lamp, the tip could be generated by the moderate temperature change cycles with moderate current modulations[3].

In AC lamp, the size and shape of the tip depend on the length of the each alternative phase. The quantity of the tungsten deposition on the tip depends on the length of the cathode phase in which cathode collects tungsten ions by the electric field, and that of the tungsten evaporates and/or melts depends on the length of anode phase in which the tip is heated up. In other words, the tip size depends on the alternative frequency. When the lamp is operating at the lower frequency, the tip size becomes larger. And also, at the higher frequency, it becomes smaller.

It is well-known that simple square-waveform operation with any frequency can not maintain the tip size and shape for the long time[1]. It seems that the operation with simple square-waveform does not have good effect on adjusting the tip shape. As a result, the tip gradually changes its size and shape, eventually the tip vanishes or multi tips are generated due to lack of balances between melting and solidification and/or between evaporation and deposition.

"UDRIVE" CURRENT SCHEME

By means of aforementioned balance, it is important to maintain preferable tip size and shape during lamp life in order to keep constant arc gap and stabilized arc. In other words, it is necessary that the lamp driver with optimum current waveform should finely control temperature of the tip not so high but sufficient to adjust the tip shape.

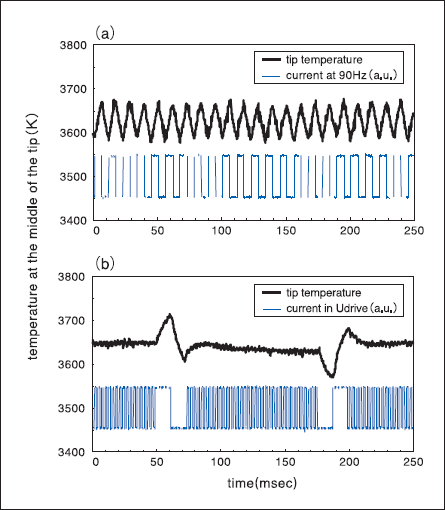

"Udrive", in which one cycle of lower frequency wave is inserted in relatively higher frequency waves, has been developed to maintain only one preferable shaped tip at the front end of the electrode. The beginning polarity of lower frequency wave is alternated at each insertion in order to adjust each electrode equally. "Udrive" takes advantages of both higher frequency and lower frequency. The higher frequency prevents the electrode temperature from becoming too low and/or high. Figure 1 shows that the temperature at the middle of the tip hardly changes at 360Hz, while it changes about 100K at 90Hz. The lower frequency has excellent function as an adjuster of the tip shape.

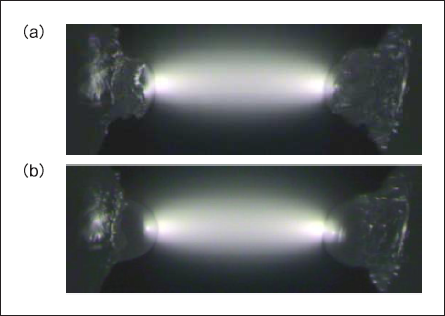

"Udrive" adjusts the tip shape so as to have smooth surface by melting necessary and sufficient areas of the tip during the anode phase of the lower frequency wave (Fig. 2(b)). Since the maximum temperature of the tip during the anode phase in the lower frequency wave depends on the beginning polarity, the beginning polarity should be alternated at each insertion (Fig. 1 (b)). We experimentally operated some lamps without alternation of the beginning polarity of the lower frequency waves. One of the electrodes for which the lower frequency wave always began in the cathode phase was lost by burn-back. "Udrive" current scheme heats up the tip in order to smooth its surface not so very often but intermittently. Therefore, heat load of the electrode would be comparatively lower than conventional superimposed pulse modulation.

Fig.1: Measured temperature at the middle of the tip In same lamp operated with different current waveform:

(a) simple square-wave at 90Hz,

(b) "Udrive" (360Hz with inserted 45Hz)

Fig.2 : Photographs of the tip at the front end of the electrodes in same lamp operated with different current waveform;

(a) simple square-wave at 90Hz,

(b) "Udrive" (360Hz with inserted 45Hz). It is shown that "Udrive" adjusts the tip shape so as to have smooth surface.

CONCLUSIONS

It is important that a preferable tip size and shape are maintained during lamp life in order to keep constant arc gap and stabilized arc by the moderate balance between melting and solidification and/or by the moderate balance between evaporation and deposition. "Udrive" can finely control temperature of the tip not so high but sufficient to adjust the tip shape. Therefore, it is possible to maintain high luminance and stabilized arc during lamp life.