光技術情報誌「ライトエッジ」No.39(2013年6月発行)

レーザー学会学術講演会 第33回年次大会

(2013年1月)

Lasers for Display and Lighting … The Time is Now

William F. Mackenzie, Greg Niven, AHidekazu Hatanaka (Necsel IP Inc., AUshio Inc.)

1. INTRODUCTION

Solid state ligh ting sources based on semiconductor laser technologies have frequently been discussed in literature and are currently being sold in lower brightness projectors, such as pico (< 50 lumens) and data projectors (< 5000 lumens). Within the last year, we have seen high power lasers applied to ultra-bright projectors with several public demonstrations from the leading digital cinema projectors companies. These technologies have delivered wider color gamut, brightest images from a digital projector (> 60,000 lumens), full brightness 3D (14 foot lamberts), higher contrast ratio (> 5000:1) and lower cost of ownership.

Through fiber optics, lasers also offer the unique property of being able to efficiently and effectively decouple where the light is produced from where you use the light. Necsel provides several types of laser solutions: multi-Watt class red, green, and blue lasers, laser modules and complete integrated laser systems. These products have been used in new and interesting applications such as endoscopes, forensics, hazardous lighting and border tubing neon. These new systems have longer lifetime, lower power consumption, less service and maintenance costs, infinite colors, new form factors, no infra-red and ultra-violet components like HID lamps, cheaper installation and no toxic materials (such as mercury).

This paper reviews the technology used for these laser products, discusses the reliability based on measured life test data and discusses the applications. The Necsel highly reliable and manufacturable lasers now exist. High volume applications are driving down the cost. Using the unique ability to efficiently couple light into small fibers, new form factor products are now being produced.

2. Laser Diodes

2.1 Green Frequency Doubled Laser Diodes

The 3 W Necsel frequency doubled green laser diode array with a fiber coupled connection (400 μm, 0.22NA). The number of visible laser beams is 48, which is composed with two rows of 24 beams. Each of the beams is single mode with a Gaussian power profile, and is parallel to one another. Therefore, the Necsel type laser does not need either fast axis collimation lens (FAC) or slow axis collimation (SAC) lensing to achieve high fiber coupling efficiency (> 85%).

2.2 Blue and Red Direct-Emitting Laser Module

The Necsel 3-5 W, direct emitting, blue laser module is fiber coupled with a NA of 0.22 and a core diameter of 400 μm. The fiber coupling efficiency is greater than 85%. The Necsel 5-8 W Red direct-emitting Laser Diode has a FAC and SAC lens and comes in either a free space or NA of 0.22 and a core diameter of 400 μm fiber coupling option. The fiber coupling efficiency is higher than 85%.

2.3 Distributed Lighting System

Inside there is a red, green and blue laser combined into a single SMA connector output that connects to a 1 mm core transport fiber. The transport fiber can be many meters long, which is then connected to a wide variety of lighting fixtures, such as diffusive fibers (looks like border tubing neon), luminaires (looks like a lighting fixture) or even an endoscopic camera tool.

3. Life Test Data

3.1 Green, Blue and Red Laser Diodes

Necsel performs many different tests on its products to ensure that infant mortality is weeded out, ongoing failure rate is low, and wear out meets the requirements of digital cinema -- over 10 years (35,000 hours) of operation. To ensure reliable designs, each of the devices goes through many military standard tests: from on-off cycling, mechanical shock, mechanical vibration, temperature cycle, high temperature storage operating life test and others. Below are examples of life test and on-off cycling tests. For all life tests, input drive current was fixed and laser output power was monitored.

3.2 Green, Blue and Red Laser Diodes Results

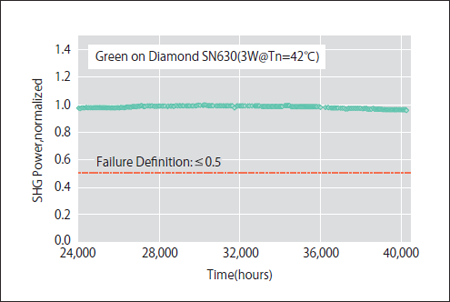

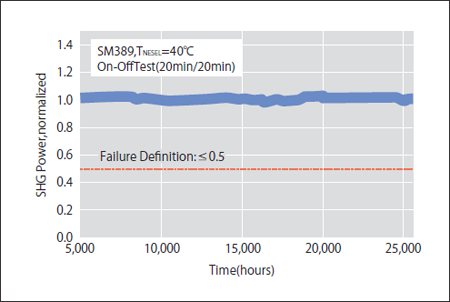

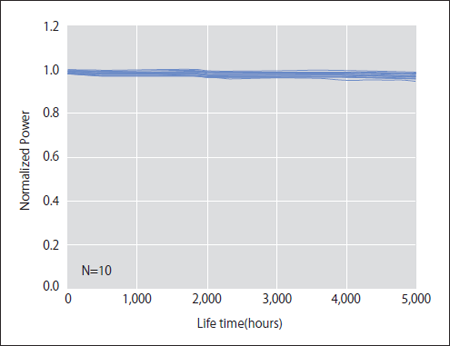

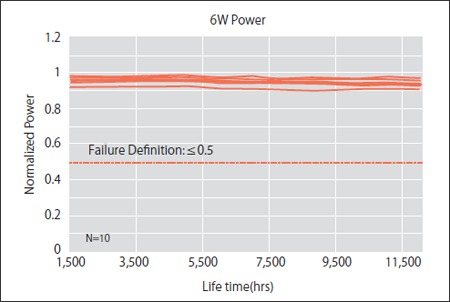

Figure 1 shows the green life test was operating at 40°C with less than 5% output power degradation after duration of 40,200 hours. Figure 2, the on-off cycling (20 minutes each) equates to 36 cycles/day, has completed 38,000 cycles, which is equivalent to > 21 years with less than 5% output power degradation. The blue life test data, shown in Figure3, has a drive current of 1.2 A with the case temperature of the TO-cans of 25°C. The laser output power is roughly 1.2 W. Results are showing > 5,000 hours with < 5% power degradation. The red life test data shown in Figure4 was carried out at an output power of 6 W with the case temperature at 25°C and driving current of 10A. The lasers have completed > 11,000 hours with no significant degradation.

The above data, in additional to other reliability data, gives us confidence that our laser s meet the targeted digital cinema application specifications of over ten year of use. This assumes these are used ten hours per day, seven days per week, and 50 weeks per year, which would be very typical for cinema projection applications.

Figure1 Green Laser life test

Figure2 Green Laser on/off test

Figure3 Blue Laser life test

Figure4 Red Laser life test

4. Applications

The leading application for volume consumption of the high power lasers is Digital Cinema. With the high cost and frequent needs to replace Xenon lamps, laser solutions offer a compelling return on investment to theater owners. This is in addition to the already strong desire to get "super bright" projectors to light up the 3D movies on the big screens. 2012 has featured several new worldʼ s records for projector br ightnes s : in January, Barco demonstrated 57,000 lumens; in September, Christie premiered 62,000 lumens [1] and then followed up in Beijing with 72,000 lumens [2]. These companies, along with other leading companies like IMAX, NEC, and Sony have already made public their intentions to bring laser-based projectors to market.

Other key applications include ones that take advantage of the laserʼ s ability to move efficiently down optical fibers (similar to those that are used for under seas communications, for example). This means that you can place the light source in a convenient location, such as inside a climate controlled area, and then route the light via the fiber optic cable to a remote location where the light is used. Necsel has demonstrated this concept in several application areas: using lasers to replace border tubing neon on the outsides of buildings, illuminating crime scenes, routing light inside the body for surgeries, making service easier for light s on radio towers , and illuminating hazardous areas where you do not want any heat or electricity. Figure 5 shows some of these sample applications.

Figure5 Sample applications

5. Summary

Several factors are influencing the market for laser-based solid state light sources at this point in time: (1) Companies releasing products based on these lasers to the market, such as ultra-high brightness projectors, driving pricing significantly lower through higher quantities; (2) Necsel demonstrating highly manufacturable and reliable red, green and blue lasers and laser modules that are able to have greater than ten year lifetimes in their targeted applications (3) Lamp leaders such as Ushio making significant in vestment in the technology and mass manufacturing and (4) Necselʼ s unique experience and products ability to generate complete systems to couple the laser light highly efficiently into fibers. These factors are creating the ability for manufactures to evolve existing products and also create new products.