The 21st International Display Workshop

(2014.12)

Difference in Speckle Reduction

by Wavelength Diversity

between Two Types of Screen

Hirotaka Yamada, Kengo Moriyasu, Hiroto Sato, and Hidekazu Hatanaka

Ushio Inc., 1194 Sazuchi, Bessho-cho, Himeji, Hyogo 671-0224, Japan

KEYWORDS: Speckle contrast, Laser display, Visual quality, Wavelength diversity

ABSTRACT

Speckle reduction by using multiple wavelength lasers were measured at two types of screen: matte screen and silver screen. Significant differences in degrees of speckle reduction were seen between two screens. The result was analyzed theoretically.

1. INTRODUCTION

Recently, laser projectors have been attractive because of their high luminance, high dynamic range, wide color gamut, and long lifetime. One of the most serious problems with laser projectors can be “speckle”, speckle is an effect caused by interference patterns of coherent light which deteriorates the image quality produced by laser projectors. One promising approach for reducing speckle noise is broadening the wavelength range of lasers1).

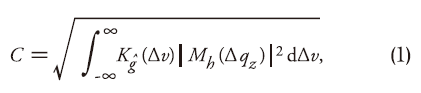

The formula of speckle reduction by wavelength diversity derived by Goodman2) is given by

where Δqz is a normal component of scattering vector difference between two different wavelengths, Mh (Δqz) is the correlation function of the two speckle fields, and Kg (Δν) is the autocorrelation function of a normalized power spectrum. Assuming that the surface-height fluctuations of screens are Gaussian with the standard deviation of σh, and that the dominant scattering type on screens is surface scattering rather than volume scattering, then |Mh|2 becomes

In this case, the property of screens is characterized by the effective surface roughness σh.

In this paper, we investigated how the use of multiple wavelength lasers affects the speckle reduction at two types of screen. We compared the experimental results with theoretical calculations obtained from Eq. (1).

2. Speckle reduction with two lasers

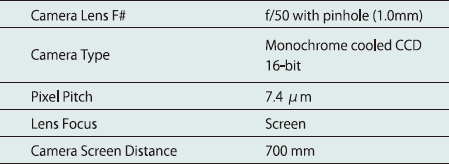

2.1 Experimental system

An experimental set-up for speckle measurement with two lasers is shown in Fig. 1. Beams from two lasers were diffused by a vibrating diffuser. Behind the diffuser, a hexagonal rod integrator was placed in order to obtain a homogeneous spatial light distribution. The edge image of the rod integrator was projected onto screens. We used two types of screen: matte screen (Harkness Screens International, Matt Plus) and silver screen (Kikuchi Science Laboratory, Finesilver240). The resulting speckle pattern was measured using a cooled CCD camera. We changed combinations of the wavelengths of two lasers, and investigated the relationship between the speckle contrast and the wavelength interval between two lasers.

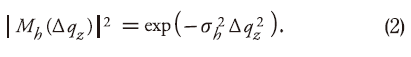

Since it is known that speckle measurement parameters affect the speckle measurement3), we carefully chose each parameter. Table 1 shows our measurement parameters.

Table 1. Speckle Measurement Parameters.

Fig. 1 Schematic diagram of an experimental system.

2.2 Results

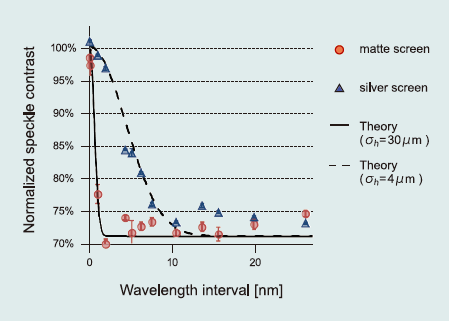

Fig. 2 shows the results of the experiment. The measured speckle contrasts of two lasers were normalized by the average speckle contrast of each laser. The solid and broken lines show the calculation results based on Eq. (1) with the surface roughness of 30 µm and 4 µm, respectively. We observed the significant difference in the dependences of speckle reduction on wavelength interval between two types of screen. Wider wavelength interval was required to reduce speckle on silver screen than on matte screen. The measured speckle contrasts were reproduced by the calculations when we set the effective surface roughness of matte screen as 30 µm and that of silver screen as 4 µm.

Fig.2 Dependence of speckle contrast of two lasers on the wavelength interval between two lasers. The measured speckle contrasts of two lasers were normalized by an average speckle contrast of each laser.

3. Speckle reduction by the use of multiple wavelength lasers

3.1 Experimental system

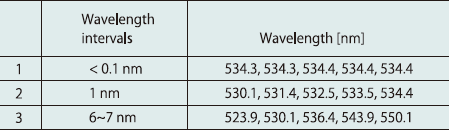

We measured the speckle contrasts on two screens illuminated by up to 5 lasers through a projector. An optical fiber bundle was set in the projector instead of a Xe lamp. Beams from the projector instead of a Xe lamp. Beams from the lasers entered into the projector through the fiber bundle. Two rectangular rod integrators were placed in the projector: one was the original integrator placed in the projector, and the other was added behind the original one. A ground glass diffuser was placed between the two rods. We used three sets of lasers of which wavelength intervals were smaller than 0.1 nm, about 1 nm, and 6~7 nm, and changed the number of lasers from one to five. Table 2 shows the wavelength list of each set of lasers.

Table 2. List of wavelength

3.2 Results

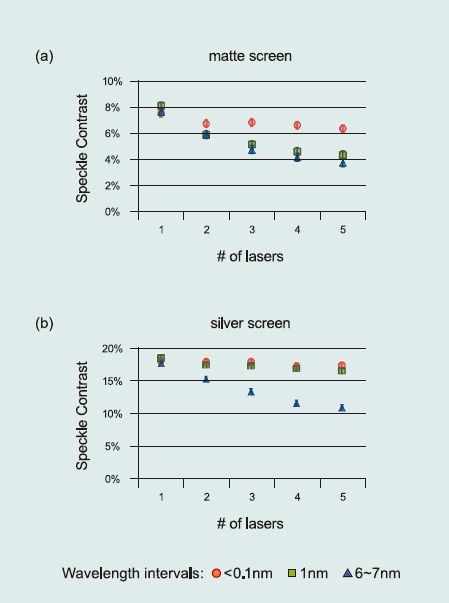

Fig. 3 shows speckle contrast dependence on the number of lasers. On matte screen, the degree of speckle reduction of 6~7 nm interval lasers was nearly the same as that of 1 nm interval lasers. In contrast, on silver screen, using 1 nm interval lasers had only a small effect on speckle reduction, but using 6~7 nm interval lasers reduced speckle significantly.

Fig.3 Speckle contrast dependence on the number of lasers at (a) matte screen and (b) silver screen. The wavelength intervals were smaller than 0.1 nm (circle), 1 nm (rectangle), and 6〜7 nm (triangle).

4. Discussion

4.1 Effective surface roughness of screen

We also measured the surface roughness of two screens by a laser microscopy system. The measured rms surface roughnesses of matte screen and silver screen were 1.8 µm and 2.1 µm, respectively. The rms surface roughness of matte screen was one order of magnitude smaller than the effective surface roughness determined in section 2.2, whereas that of silver screen was only twice smaller than the effective surface roughness. We would speculate that the reason why the difference between surface roughness measured by laser microscopy and determined by speckle experiment was so large on matte screen is that multiple scattering and volume scattering is likely to occur on matte screen. In contrast, since the single, surface scattering is a dominant type of scattering on silver screen, the surface roughness measured by laser microscopy was close to the surface roughness determined by speckle measurement.

5. Conclusion

Speckle contrasts with multiple wavelength lasers were measured at two types of screen. We found that there was a significant difference in degrees of speckle reduction between two screens. It was revealed that wider wavelength interval is required to reduce speckle on silver screen more than that required on matte screen.