光技術情報誌「ライトエッジ」No.3(1995年秋発行)

特集 第7回光源の科学と技術に関する国際会議

(当社発表論文)

高温におけるWワイヤーの引っぱり強度

TENSILE STRENGTH OF W-WIRE AT HIGH TEMPERATURES

技術研究所 応用開発部 池上秀之

Introduction

連続点灯する白熱電球の寿命は、Wフィラメントのクリープ特性に依存する。しかし、複写機の露光用ハロゲンランプは、連続点灯ではない。点減点灯する場合、ランプ中のWフィラメントが受ける熱ストレスは、連続点灯するランプが受ける熱ストレスより大きい。

本報では、Wフィラメントの高温における機械的特性と点灯点滅駆動する場合のランプの寿命との関係を明らかにする。更に、点滅点灯駆動しても長寿命を実現できるWワイヤーについても示す。

Experiments

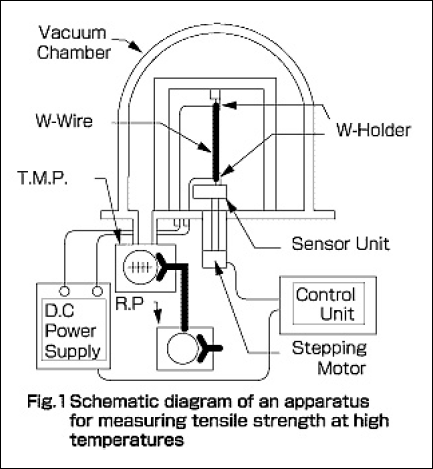

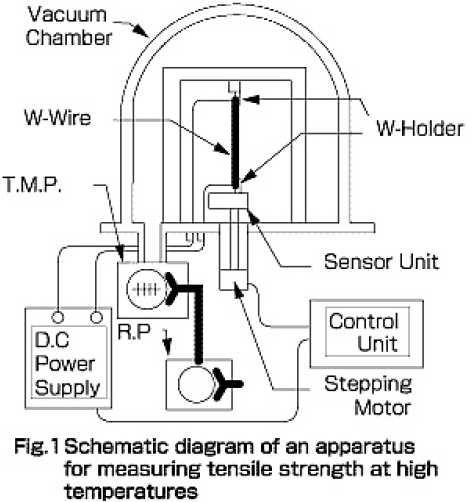

Fig.1に設計、製作した実験装置を示す。本装置を用いて、高温抗張力、及び高温クリープ特性の測定を行った。また、ランプの寿命試験は、80V-260Wの複写機用ランプを点滅点灯させ行った。

Results and discussion

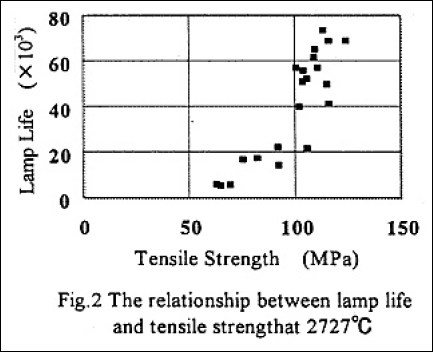

Fig.2にランプ寿命と高温抗張力との関係を示す。高温抗張力とランプ寿命との間には、強い相関性があった。しかし、クリープ速度や結晶粒径とは、相関が見られなかった。

点灯点滅駆動するランプは、高い熱ストレスが加わる。その為、Wフィラメントの結晶粒が変形し、破断が起こる。Wワイヤ一の高温抗張力は、Kドープ孔による分散強化機構によって、結晶強度が高められ、高温での抗張力が増加するためと思われる。

Conclusion

- • ランプ寿命は高温抗張力と強い関係があり、50Mpaでのクリープ特性とは相関性が見られなかった。

- • Wワイヤーの高温抗張力はK濃度に依存し、結晶粒径には依存しない。

- • Wフィラメントの破断は、結晶粒の変形に起因し、Kドープ孔による分散強化とランプ寿命とは相関性がある。

- • 点灯点滅するランプで長寿命を実現させるためには、Wワイヤーの高温抗張力を増加させると良い。

TENSILE STRENGTH OF W-WIRE AT HIGH TEMPERATURES

Hideyuki Ikegami, Tatsushi Igarashi, Tatsumi Hiramoto

USHIO Inc.Research and Development, 1194 Sazuchi, Bessho-cho Himeji-City, Hyogo-pref.671-02 Japan

1.Introduction

In general, the lamp life of incandescent lamps depends upon a creep property of the Wfilament.1) The halogen lamps for an exposure light of copier machines are operated flashingly, not continuously.The life of these lamps is mainly controlled by the thermal stress due to rapid variation in the temperature of the filament, not by the creep.A W-wire with high tensile strength at high temperatures is a key-material for the halogen lamps with long lives in the case of the exposure lamps in the copier machines.The W-wire for halogen lamps having long lives even at the flash operation has been investigated in this research.At first, an apparatus was designed and constructed in order to measure the tensile strength at high temperatures.In this paper this apparatus is explained and then a relationship between the life of the halogen lamps for copier machines and the tensile strength measured at high temperatures in the apparatus is shown.

2.Experimental

(a)Apparatus

A schematic diagram of an apparatus for measuring a tensile strength of the W-wires at high temperatures is shown in Flg.1.The W-wires of 99 to 173µm in diameter and 100mm long can be hold with W-holders. The apparatus is evacuated by a turbo-molecular pump(T.M.P) below 10- 3 Pa. Atmosphere such as oxygen is also available. After the W-wires were recrystallized by resistively heating them at 2727°C the tensile strength was measured at 2227°C, 2493°C, 2727°C,3004°C. Many W-wires manufuctured in various processed were tested.One Wholder with the sensor unit shown in Fig.1 moves down at a speed of 1mm/min.

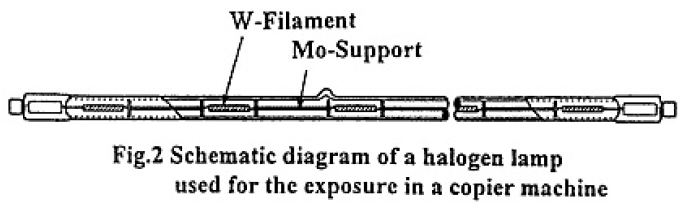

(b) Lamp

The wires in a lot had been grouped at random into two sub-groups.One was for measuring the tensile strength at high temperatures and the other was for the filaments of the halogen lamps with standard specifications for the exposure.An example of the lamps is shown in Fig.2.These lamps were operated under the following standard condition:1.3sec ON-0.2 sec OFF,this ON-OFF is repeated 250 times,then a pause for 300sec,and this cycle is repeated.The input power during ON-time is 260W at 85 VAC.

3.Result&Conclusion

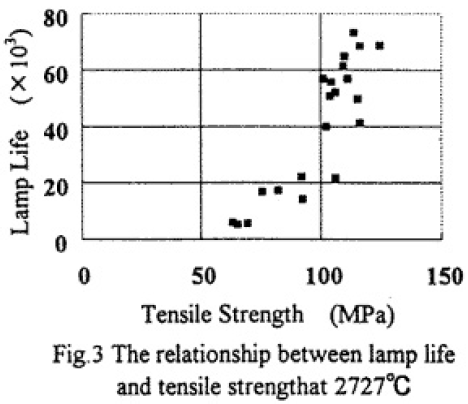

Fig.3 shows the relationship between the tensile strength of the W-wires at 2727°C and the lamp life.It was found that the lamp life has a direct correlation to the tensile strength at 2727°C of the W-wires belonging to the same manufacturing lot of the lamp filaments.As a result the lamp life can be estimated from the tensile strength at 2727°C.It can be concluded that the life of the halogen lamps flashingly operated is dominantly influenced by the thermal stress of the filament wires.The halogen lamps flashingly operated with long lives has been developed with increasing the tensile strength of the W-wires at high temperatures.