光技術情報誌「ライトエッジ」No.40(2014年3月発行)

平成25年(第66回)電気関係学会九州支部連合大会

(2013年9月)

A monolithic PDMS spectroscopic analyzer

Fan Yang* Hiroaki Yoshioka* Kinichi Morita** and Yuji Oki*

(* I.S.E.E. Kyushu University) (**Ushio INC.)

1. Introduction

A monolithic polydimethylsiloxane (PDMS)spectroscopic analyzer was fabricated using a mold, which was printed by 3D printer. Compared with the previous design [1], this design reduces the device size and has better performance in elimination of stray light for clean fluorescence. However, in order to perform high-accuracy measurements for detecting a small amount of samples, the scattering light and the stray light must be intercepted with high extinction ratio. It can be achieved by designing and fabricating an optical system of a complex folding for extracting only the signal light. In this paper, we present our design and fabrication of a folding monolithic PDMS spectroscopic analyzer using 3D printer. Meanwhile, in order to eliminate the stray light better, we did optical characteristic evaluation of black PDMS and conducted experiments for optimization.

2. Experiment

2.1 Optical system

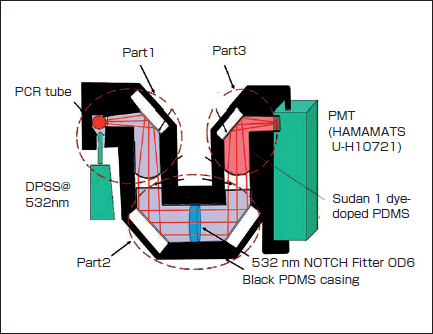

Fig.1 shows the optical path of spectroscopic analyzer. The whole system includes 3 parts as shown in figure 1.

In part 1, the PCR tube of dye solution is irradiated by a DPSS at 532 nm to release the fluorescence. Critical reflection occurs when the light strikes the boundary between transparent PDMS and air at 47°~46°.The reflected light becomes parallel after going through the lens (Φ=10mm, f=26mm) because PCR tube is placed at the focus of the lens.

In part 2, after a second time of cr itical reflection, the parallel light travels through a NOTCH Filter with OD 6 (Optic Density 6) which eliminates a part of straylight at 532nm. After another critical reflection, the parallel light goes into part 3, which is Sudan I Dye-doped Ethanol at a concentration of 18.0 mM was placed in a container and kept it for 24 hours at room temperature. [2]

In part 3, the parallel light travels through a lens (Φ=10mm, f =26mm) for eliminating stray light at 532nm, and after another critical reflection at the boundary, the parallel light focuses at PMT (HAMAMATS U-H10721). Finally the sensor receives clean fluorescence. Additionally, this design also includes the Absorption Filter, Reflected Filter, and Critical Reflection Filter to eliminate stray light.

Fig. 1 chematic diagram of monolithic PDMS spectroscopic analyzer

2.2 Optical characteristics of the black PDMS

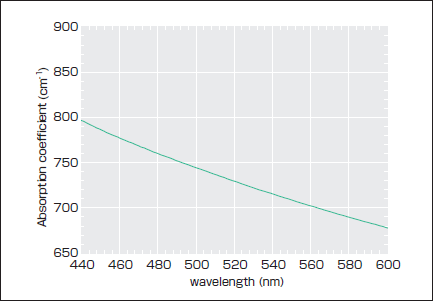

Fig.2 shows the absorption coefficient of PDMS, with a thickness of 0.1cm and 1 wt% carbon mixed inside. When wavelength reaches 532nm, the absorption coefficient is 720.736 cm-1. By applying the Lambert-Beer law, we can calculate carbon concentration in PDMS based on known thickness, transmittance and absorpti on coefficient. According to measurements, the scattering light on the surface of 3cm-thick black PDMS (carbon concentration: 1%~20%) is about 0.6% of that on the surface of white paper (100% scattering light). This indicates that black PDMS has much higher Extinction Ratio for light at 532nm, which means most stray light is eliminated.

Fig. 2 Absorption coefficient of 1wt% carbon mixed in

3. Production Process of Mold

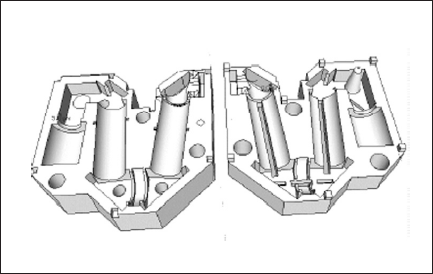

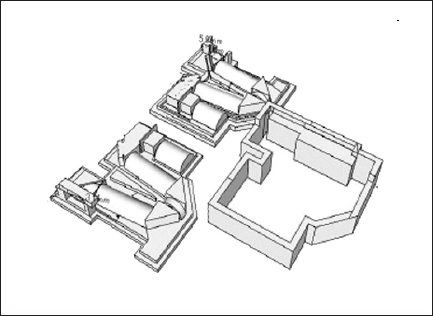

According to schematic diagram shown in Fig1, we design a three-dimensional PDMS optical path mold (shown in Fig.3) by Sketchup. To eliminate the stray light coming from the outside of the system, we also design a black PDMS casing which was made by mixing carbon inside the PDMS. The 3-D design diagram of its mold is shown in Fig.4. Both molds are printed out by a 3-D printer at the end.

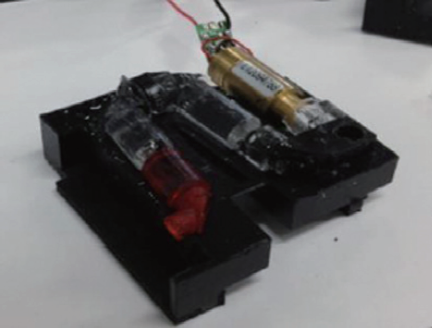

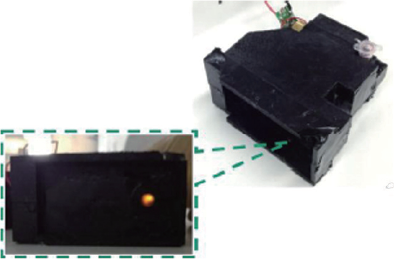

Fig.5 shows the internal structure of the spectroscopic analyzer and Fig.6 is picture of the Overall structure of PDMS spectroscopic analyzer. As shown in Fig.6, clean fluorescence is observed at the center of PDMS optical path, which justifies our corresponding calculation and design.

Fig. 3 Design of PDMS optical path mold

Fig. 4 Design of black PDMS casing mold

Fig. 5 Inside of the spectroscopic analyzer

Fig. 6 working of the spectroscopic analyzer

4.Conclusion

Based on the optical characteristics of the black PDMS and the critical reflection theory, we design and fabricate a folding monolithic PDMS spectroscopic analyzer with smaller size, which gives very satisfying results.