Contribute to a Sustainable

Society through Business

Basic Approach

Ushio has created a vast array of products by leveraging the technologies it has cultivated since its founding. This product creation has been strongly supported by our core technologies for controlling light, and our keen ability to perceive social issues. Going forward, we will continue to utilize our core technologies to provide solutions that resolve social issues, thereby supporting human well-being and societal growth.

The New System and Technology Strategy Division

The Corporate Technology Division is responsible for medium- to long-term technology development and the launch of new technology-driven businesses. In fiscal 2025, it adopted a two-division structure: the Technology Strategy Division, which formulates technology strategies linked to business and supports research and development, and the Research and Development Division, which conducts research and development for new technologies and businesses.

The Technology Strategy Division’s mission is to collaborate with the Marketing Management Division of the business division to formulate a medium- to long-term company-wide roadmap, and, aligning technical feasibility, time constraints, and engineer capabilities, formulate a technology roadmap. We believe that skill management, training, and appropriate resource allocation for Ushio’s engineers are all essential to achieving the goals of the technology roadmap, so initiatives in this area are implemented concurrently. The division also evaluates development themes for Ushio as a whole, including those within the Corporate Technology Division. Based on the evaluation results, it not only recommends discontinuing certain development themes, but also monitors the progress of each theme to identify shortcomings and high-risk areas for commercialization, and provides support and follow-up as necessary. Starting in fiscal 2025, we have adopted a stage-gate approach to clarify the ideal focus at each phase of development, reducing risks related to resource allocation.

The Research and Development Division will follow the medium- to long-term technology roadmap to solve technical challenges that are difficult for business divisions to handle. Starting in fiscal 2025, it will also work with the Technology Strategy Division to generate new ideas for business creation.

Creating Businesses That Offer Social Value Through Light

Interference Lithography

The Limits of Manufacturing in the Photoelectric Fusion Trend

As competition in generative AI intensifies, the enormous electricity consumption of data centers has become a significant issue. To address this, a global shift toward photoelectric fusion is emerging. In this approach, laser light sources, which are currently placed outside the printed circuit board (PCB), will eventually be mounted on an interposer, replacing electrical signals used for sending and receiving data with light signals.

The closer the laser light source is to the chip, the greater the volume of data handled by light, so it is expected that more lasers will be required.

The laser light source used in photoelectric fusion is called a distributed feedback laser diode (DFB-LD), which features a diffraction grating along its waveguide. Demand for these devices is currently so high that production cannot keep up. One reason for this is the extremely high precision required for diffraction gratings in DFB-LDs. The pitch accuracy must be less than 1 nm, a level unattainable with conventional manufacturing technologies.

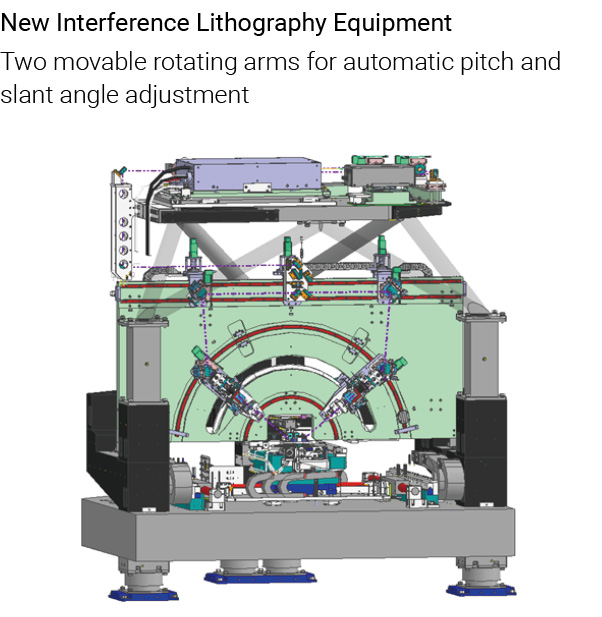

New Interference Lithography Equipment Achieving 0.01nm Pitch Accuracy for Photoelectronic Fusion DFB-LD Manufacturing

Ushio is developing entirely new interference lithography equipment to support the laser light source manufacturing technology required for photoelectronic fusion. Its key feature is the direct measurement of interference fringes with 0.01 nm accuracy, using adaptive optical metrology to correct any deviations from the target. This capability ensures the pitch accuracy required for DFB-LD diffraction gratings, contributing significantly to the advancement of photoelectric fusion technology.

Using Interference Lithography to Achieve Previously Impossible Phase-shift Structures

One reason interference lithography has not been adopted for mass production of DFB-LDs is the inability to form a phase shift layer. The phase shift layer is known to improve the yield of the laser by introducing a discontinuous shape to part of the diffraction grating. Thirty years ago, a corrugation pitch modulated (CPM) structure with functions equivalent to a phase shift layer was proposed for interference lithography. However, at that time, interference lithography was not yet at a level suitable for mass production, and electron beam (EB) lithography equipment took the lead. By combining the CPM structure with a highly controlled diffractive optical element (DOE), we have successfully created a CPM structure equivalent to a phase shift layer.

Working to Create the World’s First Mass-Production Compatible Interference Lithography Equipment

Conventional interference lithography technology is highly susceptible to environmental influences and has not reached a level suitable for mass production. By incorporating innovative lithography technologies developed through Ushio’s expertise in lithography equipment for semiconductor manufacturing, we offer new interference lithography equipment that is highly automated and exhibits excellent stability against environmental conditions and vibrations, making it the world’s first such equipment suitable for mass production.

Decomposition of Per- and Polyfluoroalkyl Substances (PFAS)

PFAS: A Global Environmental Issue

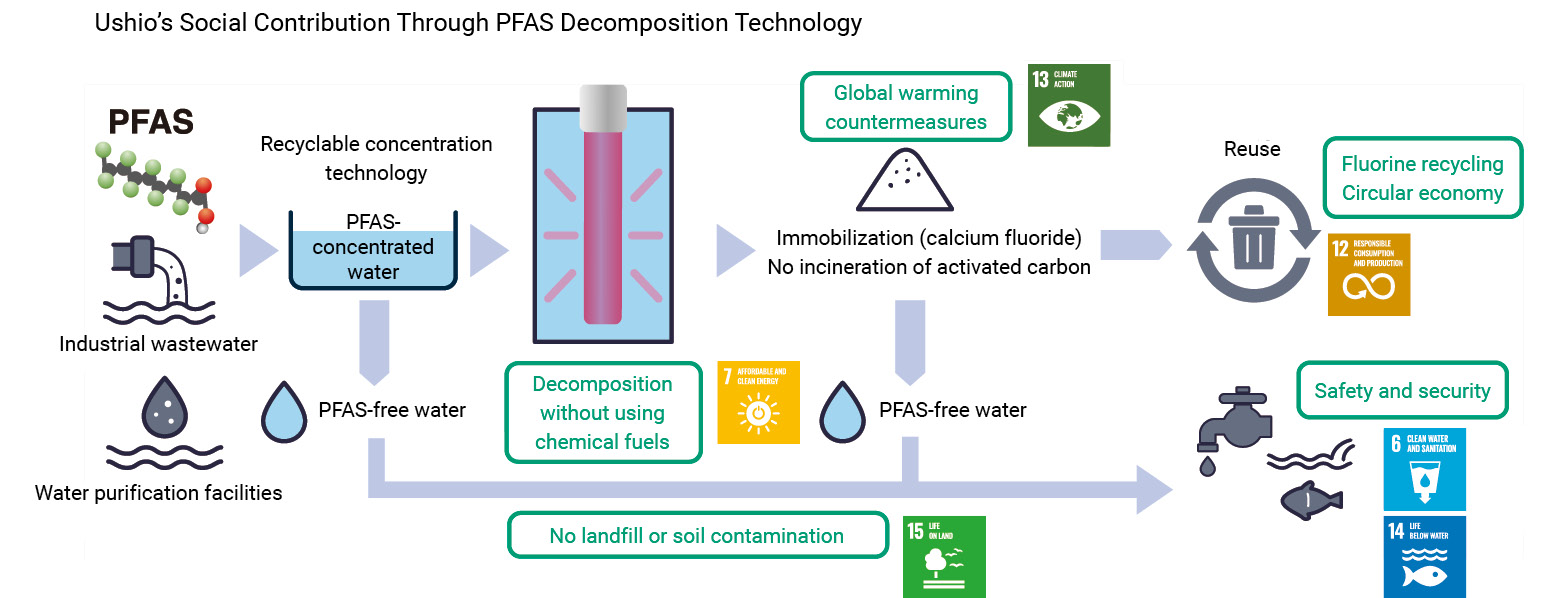

Since reports emerged linking PFAS to human health issues, strict emission regulations have been established in regions such as Europe and the United States. However, the persistent nature of PFAS has made their removal and detoxification an urgent challenge. Current PFAS treatment methods involve high-temperature incineration after adsorption onto activated carbon. However, concerns remain regarding the fuel and energy consumption required for transporting and incinerating the activated carbon, as well as the CO2 released into the atmosphere during its incineration.

Ushio’s Per- and Polyfluoroalkyl Substances (PFAS) Decomposition and Detoxification Technology Utilizing Excimer Light

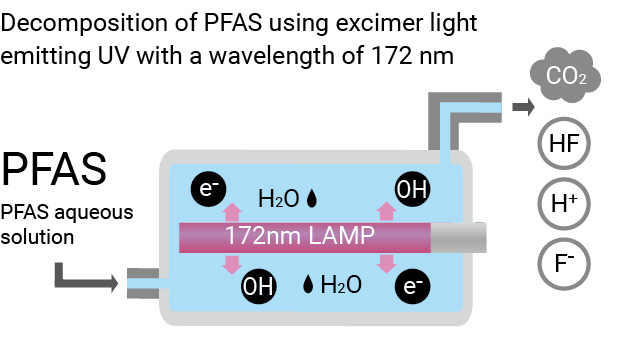

Leveraging vacuum ultraviolet technology (172 nm wavelength, xenon excimer lamp) developed since its founding, Ushio has created a technology that uses light to decompose and detoxify PFAS without the use of fossil fuels, catalysts, or additives. After decomposition, PFAS is fixed and stabilized as calcium fluoride. Ushio’s technology enables on-site decomposition, eliminating combustion and minimizing CO2 emissions, thereby contributing to a safe and secure fluorine recycling society while simultaneously helping to curb global warming.

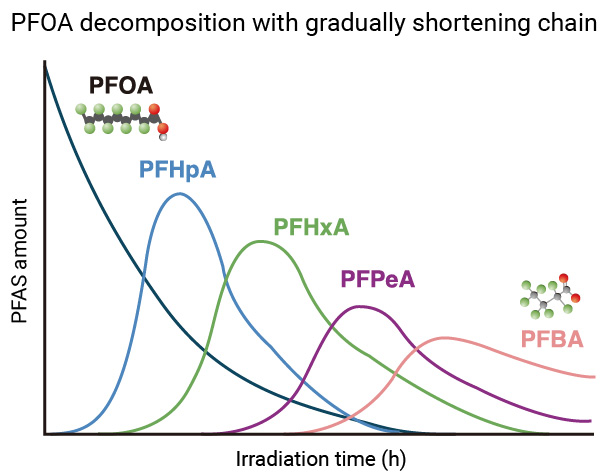

Effective Against Short-Chain PFAS

As long-chain PFAS break down into shorter chains, their light absorption shifts to shorter wavelengths, preventing absorption of general light (visible light, UVA and UVB). Ushio’s excimer lamp emits light at a short wavelength of 172 nm, which can be absorbed by short-chain PFAS. This, combined with radicals generated by the light, enables decomposition of even the most difficult short-chain PFAS.

Increasing Decomposition Rate by Combining with Concentration Technology

PFAS in water are often highly diluted, so concentrating them would improve light utilization efficiency. Research and development is currently underway to commercialize this technology, and a proposal combining Emulsion Flow Technologies Ltd.’s solvent extraction technology and Ushio’s photodegradation technology was selected for the Ministry of the Environment’s fiscal 2025 Demonstration Project on PFOS Reduction. Moving forward, we aim to commercialize the project by 2027, targeting markets for industrial wastewater, tap water, seepage water, and groundwater.

Policy on Green Products

Impacts on climate change span the entire business. In particular, manufacturers that provide energy-using products, such as Ushio, tend to have a higher percentage of the impact on climate change from the use of their products, which poses a significant risk. However, in a situation where various companies are tackling climate change, if they develop products that have less impact on climate change, we believe this will be an opportunity for customers to choose.

With the theme of creating safety, reassurance, and environmentally conscious solutions, Ushio has expanded this scope to include all business areas, including products, development, and services. In order to promote environmentally conscious design and development that contribute to energy saving, we have established energy saving items as one of our own certification standards for Super Green Products, and have been continually contributing to energy saving through the promotion of sales of certified products.

In fiscal 2023 and beyond, we will continue to work on reducing CO₂ emissions during product use as part of our materiality (important issue). We will continue to develop energy-saving products, including super green products.

Plan for Reducing CO₂ Emissions Using Development of Green Products and Actual Results

| Plans | Status of achievement* | Actual results | |

|---|---|---|---|

| FY2024 | Reduce Scope 3 Category 11*1 CO₂ emissions by 17.5% compared to FY2017 | ✓ | Reduced Scope 3 Category 11 CO₂ emissions by 27.3% compared to FY2017 |

|

Introduction of Green Product and Super Green Product standards based on Ushio Group's unified environmental product evaluation and environmental factor calculation, and start of phased operation |

✓ |

Registered the new Environmental Product Assessment Guidelines in Ushio's Quality and Environmental Management System and disseminated the contents throughout all Ushio Group. |

|

|

GP product ratio*2 of 75% or more and SG product ratio*2 of 10% or more, based on Ushio Group's unified environmental product evaluation |

- |

Green Product ratio of 69% and SG product ratio of 3% , based on Ushio Group's unified environmental product evaluation |

|

|

Establishment of a method to calculate CO₂ emissions from basic data of the entire group in FY 2017, which is subject to Scope 3 , that is valid and in line with the GHG Protocol guidelines and acquisition of third-party verification certification |

✓ |

Calculated CO₂ emissions for Scope 3 based on group-wide data following the GHG Protocol guidelines, and obtained certification through third-party verification. |

|

| FY2025 | Reduce Scope 3 Category 11 CO₂ emissions by 29.7% compared to FY2017 | ||

|

Achieve Green Product ratio of 75% or higher and Super Green Product ratio of 10% or higher, based on Ushio Group's unified environmental product assessment |

|||

|

Roll out Green Product and Super Green Product standards to all Ushio Group, based on unified environmental product assessment and environmental factor calculation |

|||

|

Manualization of method to calculate CO₂ emissions, establishing it within Quality Management System (QMS), and obtaining third-party verification, all in accordance with GHG Protocol Guidelines, using FY2017 baseline data for Group-wide SCOPE3 emissions |

|||

| Medium to long term |

|

||

|

|||

* ✓: achieved; ―: not achieved

Development of Environmentally Conscious Products

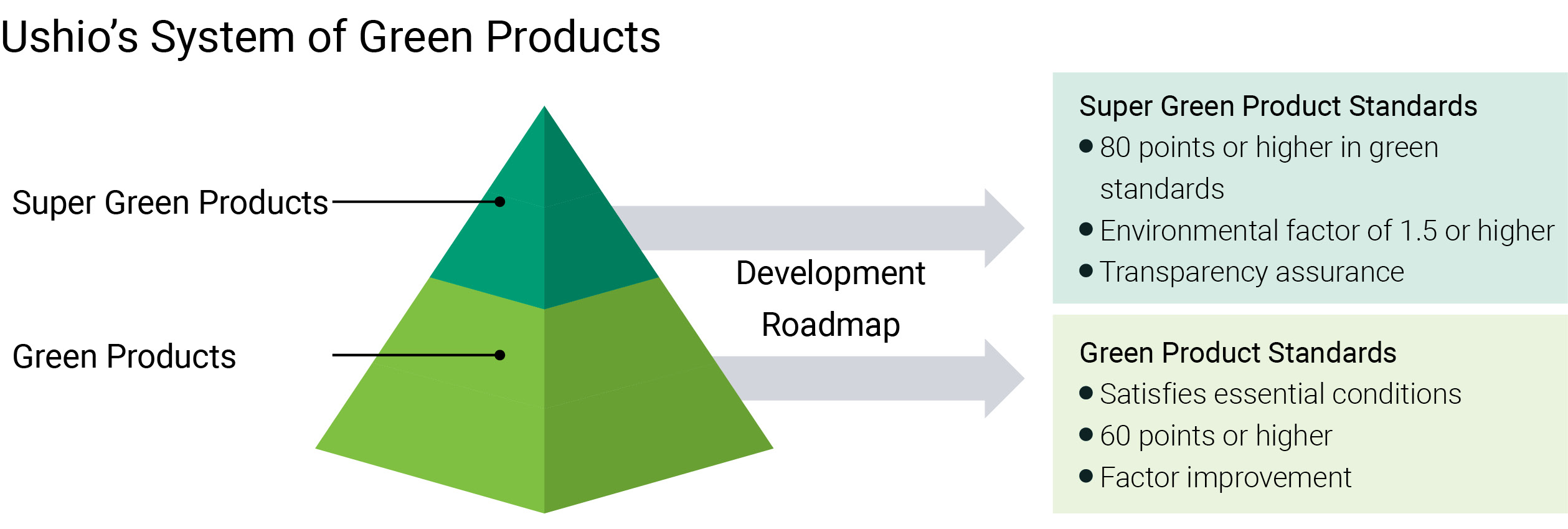

At Ushio, we incorporate our Green Product Assessment Manual into our Design Standards so we can pre-evaluate the environmental impact of our products starting in the design stage. When the environmental performance of a product has been improved based on this evaluation, it is certified as a "green product." If a product is outstanding even among green products, and uses innovative environmental technology on a completely different level from existing products, it is certified as an SG product.

Development of Super Green Products

We are working to create green products and certify products that actively employ innovative environmental technologies as "super green products" in accordance with our own certification criteria. Super green products are front-runner products with excellent environmental performance in terms of energy savings, long-term use, 3R design, materials used, and applications. These products have cleared numerical standards by Ushio Environmental Factor. Currently, many of our products are certified as super green product.

Evaluation Criteria of Super Green Products

The certification standard for Super Green products is comprised of the following three requirements.

1) Green product score of 80 or more (based on green product assessment standards)

2) Environmental factor of 1.5 or more (calculated in comparison to previous products, with FY2015 as the baseline year)

3) Attainment of transparency

Environmental Factor

Environmental factor is calculated by dividing the environmental efficiency of the target product by the environmental efficiency of the equivalent product in the baseline year. Ushio calculates a product's environmental efficiency by dividing product value (performance) by environmental impact. Product value is calculated by multiplying energy output by lifespan. Environmental impact is calculated with this formula: √ [(Energy input)²+(3R volume)²+(Chemical substances content)²]

1. Energy output: For lamps, primarily lighting output and intensity in the necessary wavelength range

2. Energy input: Energy consumed in using the product

3. 3R volume: Product size and weight (quantity of resources used)

4. Chemical substances content: Quantity of substances with environmental risk contained in the product. For example, if the environmental factor is α for a given product, it signifies the following improvements over the baseline year

・A product performance improvement by a factor of α, assuming the product environmental impact is held constant. A product environmental impact reduction by a factor of 1/α, assuming the product performance is held constant

Actions Regarding Green Products

When designing products, Ushio is required to conduct a green product assessment. This assessment of green products includes more than 60 points to be cleared, and we designate products that satisfy such necessary benchmarks, including improvement of environmental factors, as green products.

Life Cycle Assessment Activities

LCA stands for Life Cycle Assessment, a method of quantitatively estimating and evaluating the resources and energy used by a product and its environmental impacts from raw materials procurement to manufacturing, use, recycling, and final disposal. Furthermore, LCA evaluate the potential environmental impact of a product.

Implementing LCA

No matter how much CO₂ emissions are reduced at factories, these activities are not meaningful if CO₂ emissions increase when the manufactured products are actually used by customers. Meanwhile, products can provide both cost and environmental benefits for customers if they use energy-efficient products. Therefore, to quantitatively measure the environmental impact of products and services over the entire lifecycle, Ushio formulated LCA guidelines in 2006 and has implemented LCAs ever since.

Product LCA Information

Used in a broad range of fields, from industrial applications to illumination and business domains, Ushio's products create an environmental load on wide-ranging fronts throughout the entire product lifecycle. We are persisting with efforts to reduce the environmental load for society as a whole by devising various environmentally conscious countermeasures and utilizing numerical values at each stage of the product lifecycle to ascertain an overall profile of the environmental load. In this manner, the Ushio Group is striving to contribute to society through conserving the environment. As part of these efforts, we disclose Life Cycle Assessments (LCA) evaluation results for lamps widely used in offices and households, including discharge lamps and lighting power sources for projectors. The results of these evaluations are utilized for improvements in product design and manufacturing processes as well as for in-house environmental education.

Specific Examples of LCA Initiatives

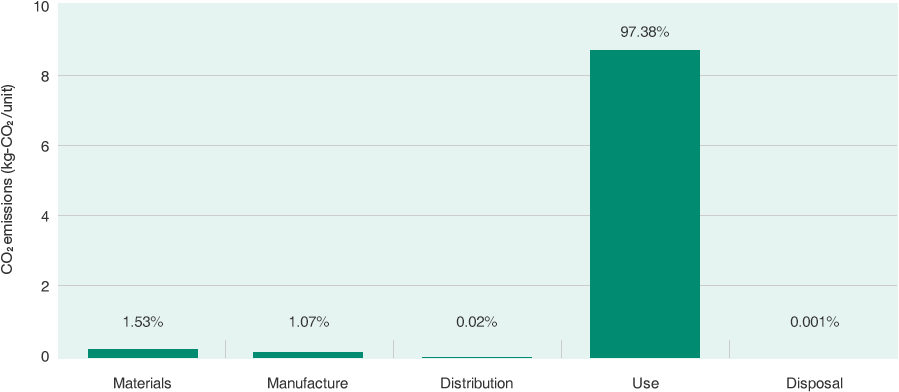

High-Intensity Discharge Lamp for Data Projectors (NSH Lamp) and Lighting Supply Source

In this case example, Ushio calculated CO₂ emissions for one lamp at each stage of the product lifecycle. We learned that CO₂ emissions during lamp usage account for approximately 98% of total CO₂ emitted during the entire product lifecycle, mainly resulting from electric power consumption. The next largest proportion of CO₂ emissions is from materials used in the lamp, which account for about 1.5% of emissions, mainly the reflector, front glass, and other glass materials. Our assessments thus reveal that CO₂ emissions are particularly large during the usage stage. The development of energy-conserving lamps is therefore crucial as an improvement measure.

Product evaluated: High-intensity discharge lamp for data projectors (Direct current lighting 300W)

Period of usage: 1,500 hours

Product flow: Materials →manufacturing (production plant) → distribution → usage → disposal

CO₂ Emissions by Life Cycle Stage

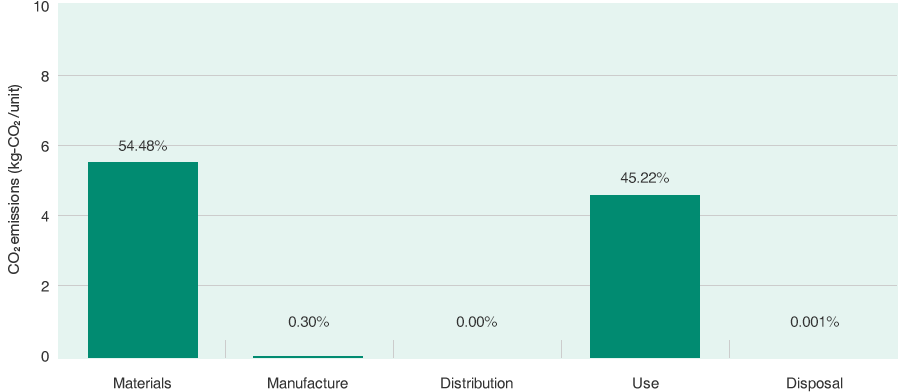

Lighting Power Source for High-Intensity Discharge Lamp for Data Projectors

In this case example, Ushio calculated CO₂ emissions for a lighting power source at each stage of the product lifecycle. We learned that CO₂ emissions occurring at the stage of the materials used in the power source accounted for around 54% of the total CO₂ emitted during the entire product lifecycle. Moreover, these materials were mainly transistors, diodes, and other semiconductor device materials. The stage responsible for the next largest proportion of CO₂ emissions is the stage of usage, which accounts for about 45% of the total emissions, mainly resulting from electricity loss. The electricity loss at this stage of usage is calculated by converting the load loss into CO₂ emissions. Our assessments thus reveal that particularly large CO₂ emissions result from materials used and from the usage stage. Improvement measures include selecting semiconductor elemental devices with a lower environmental load, reducing the number of semiconductor elemental devices that cause large environmental loads by improving power source circuits, and raising the efficiency of lighting power sources by developing energy-saving technologies.

Product evaluated: Lighting power source for high-intensity discharge lamp for data projectors (AC lamp NSHA 230W)

Period of usage: 11,750 hours (3.5 hours per day for 100 days per year over five years: based on the Japan Environmental Management Association for Industry's EcoLeaf Program, Product Specification Criteria (PSC) for data projectors, No. AG-03)

Product flow: Materials →manufacturing (production plant) → distribution → usage → disposal

Volume of CO₂ Emissions at Each Stage of the Product Lifecycle

* This power source is manufactured overseas and thus we have excluded the shipping stage.

* For the same reason, we have used values related to production in Japan for CO₂ conversion unit values.