Conserving Resources

Reduction of Resources

Ushio’s Environmental Policy requires that it make efforts to conserve resources. We are now reducing the amount of resources that we use following this policy. Specifically, we have put into place a system for assessing weight reduction (resources used) in our assessments of environmental factors during product design and we are working to reuse packaging materials.

Initiatives for Water Usage Reduction

The countries and regions where the Ushio Group is based, both in Japan and overseas, include various areas where droughts affect water intake, and areas where water is available but access to safe water is limited due to sanitation issues.

The same attitude of taking good care of water resources needed around the world is required of companies. We also recognizes the need to properly confront, understand, and manage water. For this reason, we have set KPIs in order to manage our efforts.

In addition, with some exceptions, we have already made progress in installation of recycling water systems in major sites, and we have found that there is little room for reduction. We will continue to reduce water usage by examining and implementing various measures. At the same time, will also continue taking action against water risks.

We conduct an overall evaluation of water stress for all of Ushio Group’s bases using WRI*1's AQUEDUCT*2. As a result, in fiscal 2021, we determined that water stress was high at two bases in the United States. We have created and are now implementing water management plans for these bases.

In addition the Water Intake for the above two sites in FY2023 was 5,439.26 m3.

*1 Water Resources Institute; an independent non-profit organization that conducts policy research and technical support on environmental and development issues to create a more sustainable future.

*2 An assessment tool for water risks in various parts of the world.

Plan for Reducing Water Resources and Actual Results

| Details | Scope | Base Year (FY2019) (m3) |

Target Year (FY2023) (m3) |

Actual results of reduction rate compared to FY2019 | Assessment | |

|---|---|---|---|---|---|---|

| FY2023 |

Reduce the Ushio Group’s water resource usage by 2% compared to FY2019

|

Ushio Group total | 465,856 | 424,602 | 8.86% | Achieved |

| Ushio Inc. Gotemba Division | 158,004 | 178,585 | -13.03% | Not achieved | ||

| Ushio Philippines, Inc. | 65,167 | 66,268 | -1.69% | Not achieved | ||

| Ushio Inc. Harima Division | 37,155 | 40,150 | -8.06% | Not achieved | ||

| ADTEC Engineering Co., Ltd. Nagaoka Division | 20,709 | 18,515 | 10.59% | Achieved | ||

| FY2024 |

Reduce the Ushio Group’s water resource usage by 2.5% compared to FY2019

|

|||||

| Medium- to long-term targets |

Reduce water resource usage by 10% by FY2030 compared to FY2019 FY2025 target: Reduce water resource consumption by 3% compared to FY2019 *Same targets for the entire Group and bases that set individual targets |

|||||

*We set individual targets and manage progress for the four sites (Ushio Inc. Harima Division, Ushio Inc. Gotemba Division, ADTEC Engineering Co., Ltd. Nagaoka Division, and Ushio Philippines, Inc.), which account for about 80% of the Group’s total water resource usage.

Initiatives for Reducing Waste

Ushio aims to realize a recycling-oriented society by 2030. Having set waste reduction targets annually, Ushio is working on resource conservation and pollution prevention tied to the actual situation of divisions.

Group companies and divisions have established their own policies and targets, under which they are working to carefully sort waste and increase the effective utilization of resources.

In order to achieve this target by 2030, we are expanding our efforts to conserve resources, such as through lamp collection and recycling.

Initiatives for Collecting and Recycling Lamps

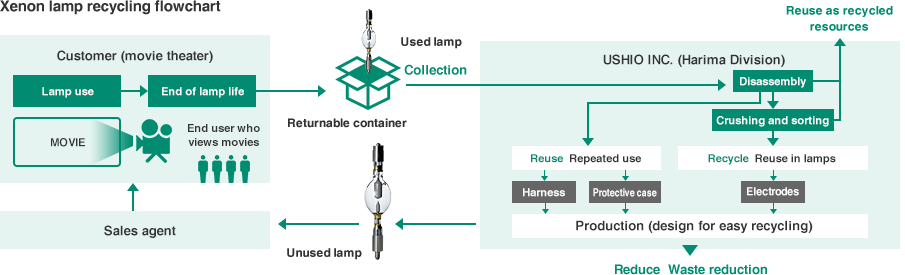

A recycling program was started in 2007 for high-pressure UV lamps for semiconductor and LCD lithography operations. We have since also launched a recycling initiative for xenon lamps for cinema projection equipment. Xenon lamps contain tungsten, one of the rare metals. Lamps collected by the program are turned into products or returned to society through 3R activities.

Please visit the link below for information on the proper collection of used mercury lamps in accordance with the Minamata Convention on Mercury and the Act on Preventing Mercury Pollution of the Environment.

Outline of JLMA - Japan Electric Lamp Manufacturers Association (JLMA)

https://www.jlma.or.jp/en/index.html

Reducing the Amount of Harmful Chemical Substances Used

Ushio is working to manage pollutants as well as reduce and prevent pollution from chemical substances that have a considerable negative impact on the environment.

Specifically, we are investigating the use of volatile organic compounds (VOCs) by each division twice a year as part of efforts by the four industry groups of JEITA, JEMA, CIAJ, and JBMIA to encourage members to reduce their VOC usage.

First, we are working to reduce our use of VOCs by reviewing our facilities up to 2030. We were able to continue our efforts in fiscal 2024.

Initiatives at the Harima Division

At the Harima Division, we are working to reduce the amount of chloroform generated in the lamp manufacturing process. Since there are concerns about pollution when chloroform is released into the atmosphere, we have introduced sealed and automated equipment, reduced the hood opening surface, and secured safety through the use of ducts. In recent years, however, due to increased production volume and further improve product quality, the amount we use has increased more than the amount reduced by our own efforts. As such, we are further strengthening our efforts.

Trend in Use of Chemicals Excluding Chloroform

Given that regulations on chemical substances are growing stricter with each passing year, we are looking to achieve even greater reductions in the amounts we use (outside of chloroform) by reducing hood opening surface and reviewing exhaust amounts when changing layouts to reduce evaporation amounts. From the perspective of creating a safer working environment, we are taking the lead in eliminating hazardous substances by considering alternatives to chemicals with high hazard levels in chemical substance risk assessments.

Initiatives at the Gotemba Division

Since 2017, as part of efforts related to the Industrial Safety and Health Act, we have been visualizing chemical substances biannually by identifying the amount of chemical substances used, and reviewing risk assessments through monthly patrols of chemical substance storage sites.

In order to prevent the outflow of hazardous chemical substances into rivers and their underground penetration, when discharging from a fluorine wastewater treatment facility into a river, for example, as part of efforts related to the Water Pollution Prevention Act, we constantly monitor the pH and fluorine concentration, and in the unlikely event that these concentrations become abnormal, we have introduced equipment to stop the discharge.

With regard to underground penetration, all pipes carrying harmful substances are redundant, so that abnormalities in the pipes can be detected immediately as much as possible without burying them. In addition, we have installed liquid barriers in places where hazardous substances are stored, and we have coated concrete to prevent underground penetration.

We also conduct monthly water quality testing of the final effluent to ensure there are no water quality issues.