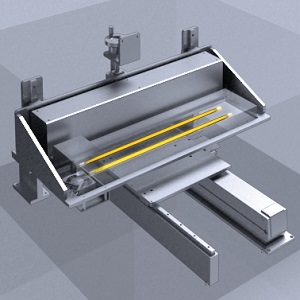

Flash lamp annealer

- Modification and Decomposition

- MEMS, Electronic Components

- Semiconductors

- Liquid Crystal Display

- Printed Circuit Board and PKG

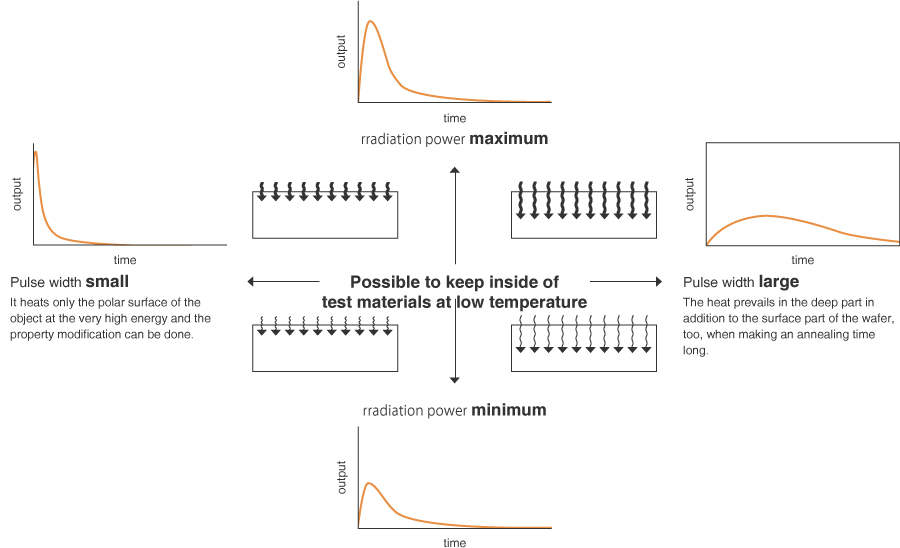

Flash lamp annealing allows very short heating processes as quick as one millisecond.

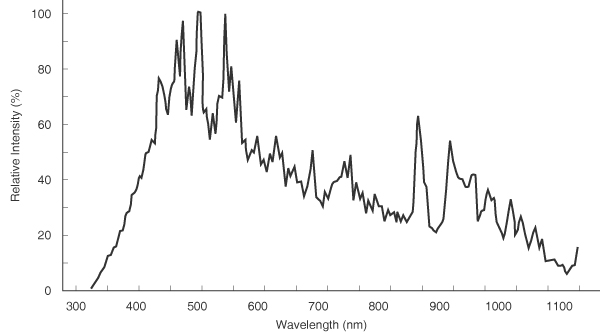

UV to visible wavelength light emitted from the flash lamp can concentrate heat on a substrate (material) surface so that the thermal influence on the underlying film or substrate

can be extremely small compared with conventional heat sources.

This millisecond surface heat treatment is becoming an essential technology for future device developments such as zero diffusion of semiconductor implanted layers and thermal budget reduction.

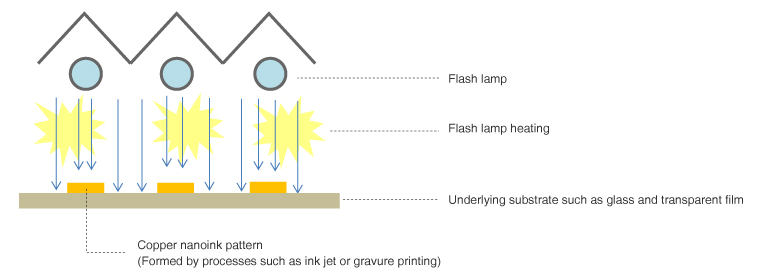

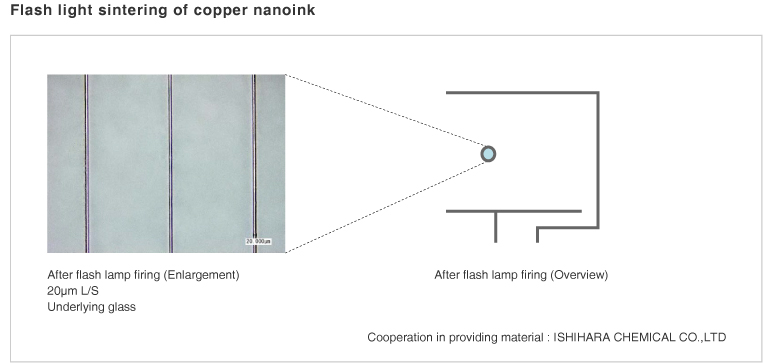

Flash lamp heating is also used to produce reactions such as crystallization, bonding, peeling, decomposition and curing. These characteristics are effectively applied in various research and development applications such as Si wafers, SiC wafers, glass, plastic films and other flexible substrates, as well as in production (manufacturing) line applications.

We welcome requests for experimental demonstrations. Please feel free to contact us.