Multipurpose exposure unit Deep UV Multilight

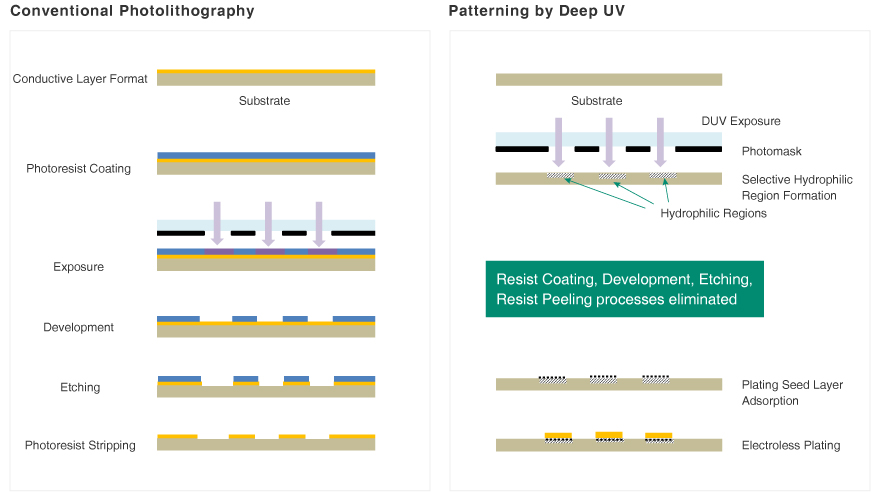

- Litho-Patterning

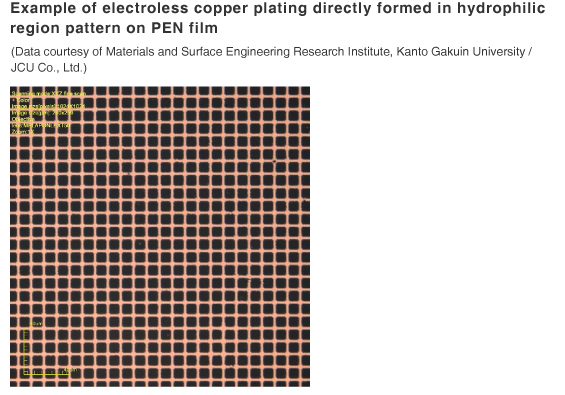

- MEMS, Electronic Components

- Semiconductors

- Liquid Crystal Display

- Printed Circuit Board and PKG

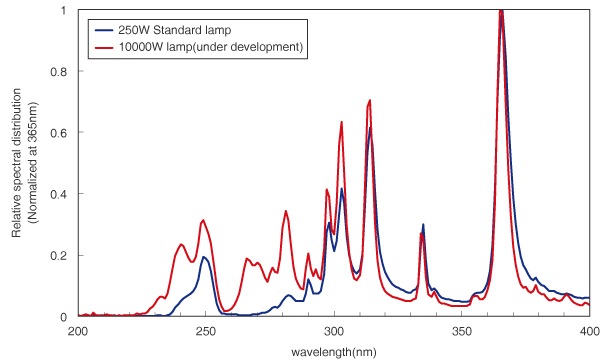

The Deep UV Multi-light is a light source unit optimized for the deep UV wavelength region from 230 to 330 nm while maintaining the same basic structure of the Multi-light series that has a good track record as a uniform, collimated light source.

It can be applied as a surface modification light source, as a light source for evaluation of various photochemical reactions, as well as for lithographic applications.